Continuous Drug Product

Product Description

CONTINUUS PHARMACEUTICALS

-

US

-

2023On CPHI since

-

50 - 99Employees

Company types

CONTINUUS PHARMACEUTICALS

-

US

-

2023On CPHI since

-

50 - 99Employees

Company types

More Products from CONTINUUS PHARMACEUTICALS (4)

-

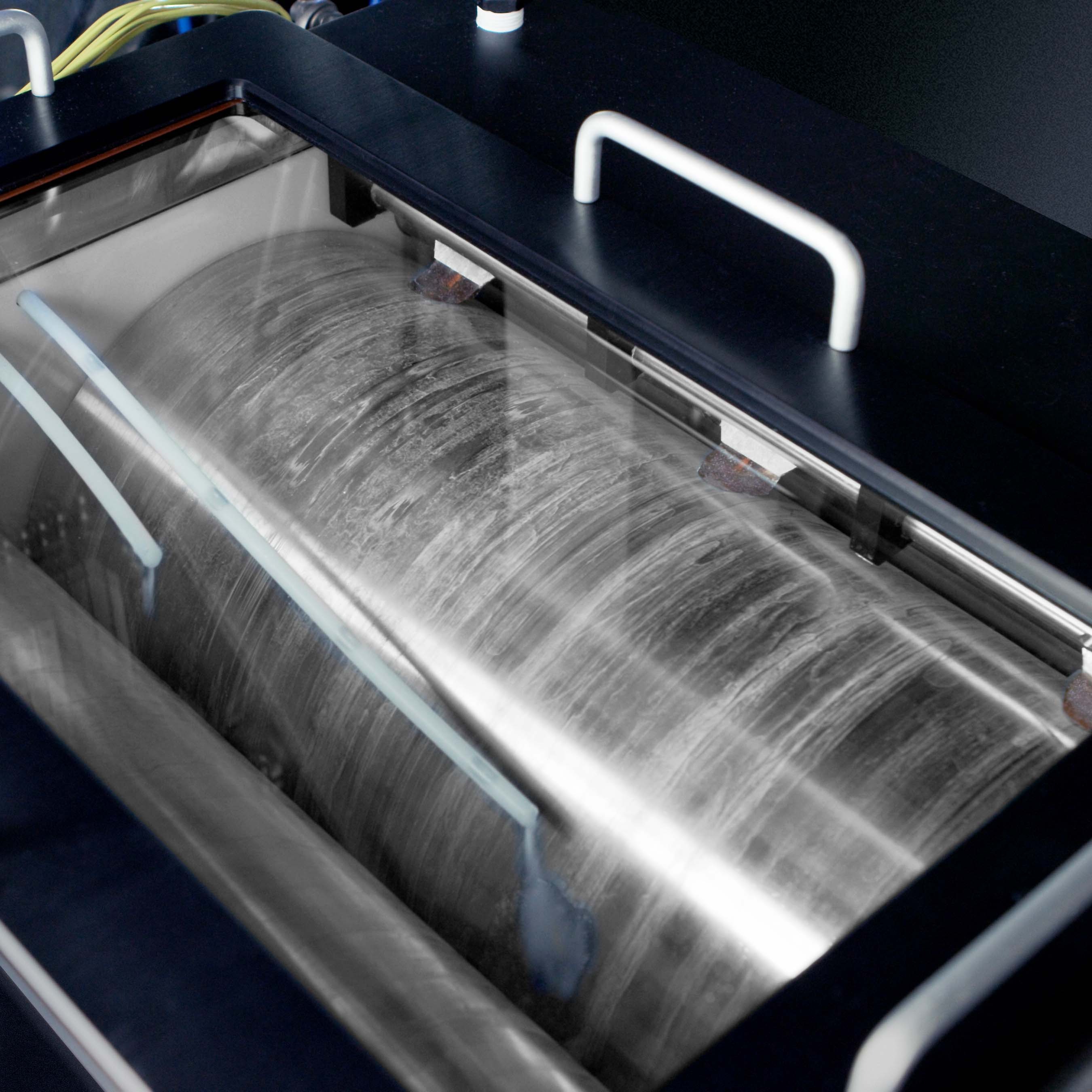

Product Dryer

Continuous Drum Dryer: Our novel continuous dryer converts concentrated or diluted suspensions containing the API into a dry, flowable powder in just a few minutes. The suspension is deposited onto two heated rotating drums, forming thin layers that are quickly dried. The entire system is under vacuum, all... -

Product End-to-end continuous manufacturing

Our technology and expertise enable seamless end-to-end continuous manufacturing processes that incorporate API formation steps with final drug product formulation. More specifically, by eliminating all the stops-and-starts that make current manufacturing processes time- and cost-inefficient, we are able t... -

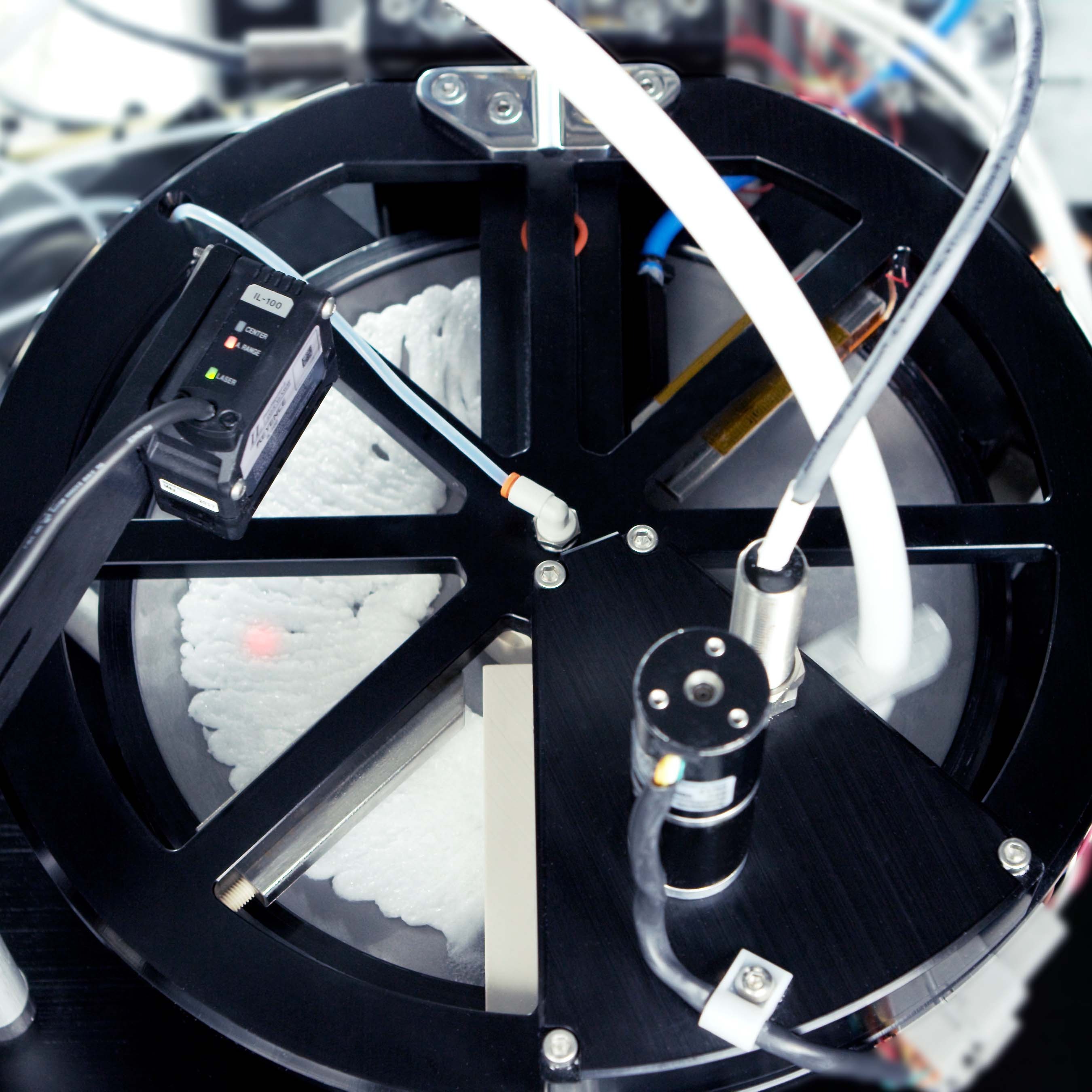

Product Filter

Continuous Rotary Filter: Our novel proprietary continuous filter purifies the crystallization slurry, removing unwanted impurities from the Active Pharmaceutical Ingredient (API) or intermediate product. This process can take less than a minute. The slurry is deposited on a rotating porous plate, where th... -

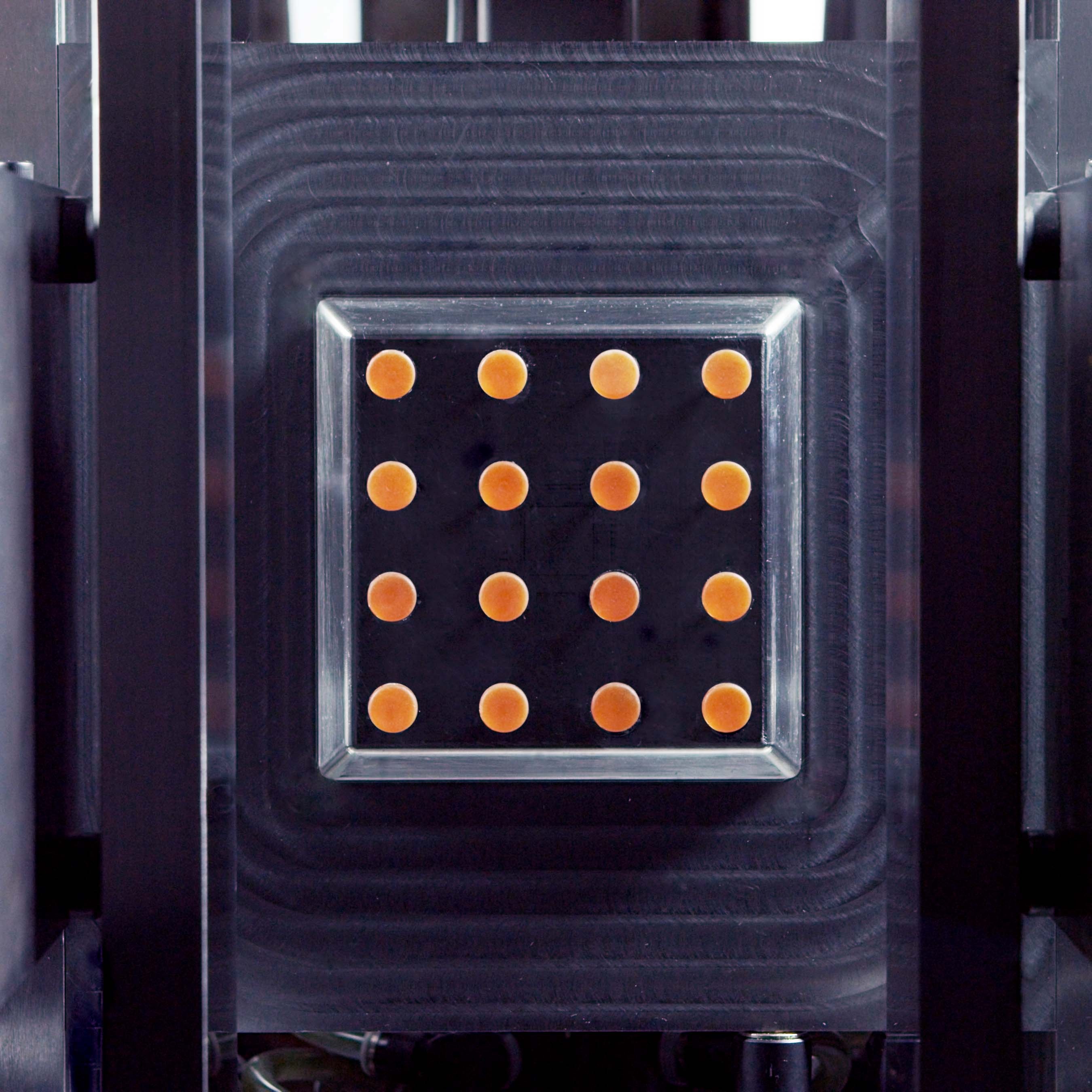

Product Flow Chemistry

Plug Flow Reactors: CONTINUUS uses custom-made reactors for single phase liquid, liquid-liquid, and gas-liquid chemistry Continuously-Stirred Tank Reactors (CSTRs): CONTINUUS uses this reactor type for reactions which contain solids, as well as for crystallizations, dissolutions, and resuspensions. Packe...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance