TURBULA®

Product Description

WAB US

-

CH

-

2023On CPHI since

-

1Certificates

-

100 - 249Employees

Company types

Categories

Specifications

WAB US

-

CH

-

2023On CPHI since

-

1Certificates

-

100 - 249Employees

Company types

More Products from WAB US (3)

-

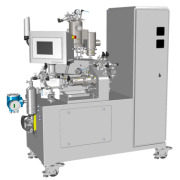

Product DYNO®-MILL

GRINDING & DISPERSION TECHNOLOGY

Wet grinding technology focuses on the controlled real size reduction, dispersion and deagglomeration of solid particles in a liquid medium. Particle finenesses in the micro to nanometer range can be achieved. For more than 60 years, WAB-GROUP&n... -

Product WAB IMPA°CT REACTOR

An inductively heated mechanochemical reactor for continuous mechanochemistry, the WAB IMPA°CT REACTOR is our latest innovation in the field of flow chemistry. An induction heater arranged around the stirring elements heats the reactants directly and efficiently up to +160 °C.

... -

Product dyna-MIX®

For a homogeneous mixture, the dyna-MIX mixes solids, solids with liquids and liquids. It is used when high-quality mixing results are required for higher quantities.

Its robust design also allows the processing of larger material quantities with high specific weights. A high-quality contro...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance