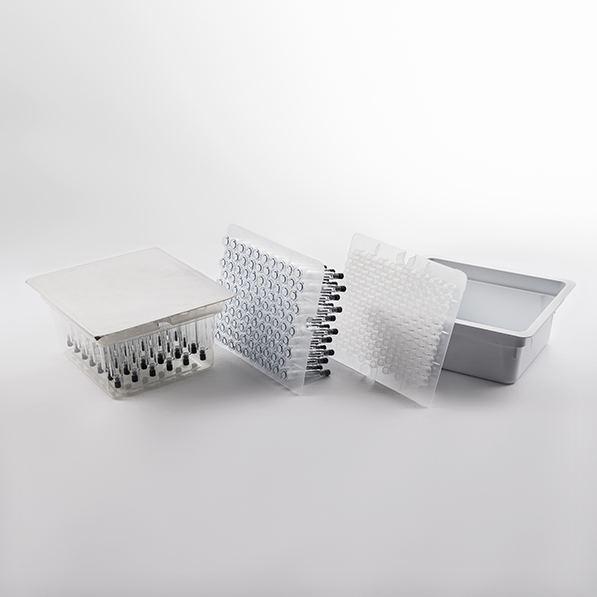

Clean room production for the life science market

Product Description

Fischer Söhne AG

-

CH

-

2021On CPHI since

-

2Certificates

-

50 - 99Employees

Company types

Categories

Fischer Söhne AG

-

CH

-

2021On CPHI since

-

2Certificates

-

50 - 99Employees

Company types

More Products from Fischer Söhne AG (2)

-

Product Canister - Packaging in all colors, shapes and sizes

We develop plastic containers for foodstuffs and for pharmaceutical and chemical products. Both standard and customer-specific canisters.

Our canisters are produced using monolayer and multilayer co-extrusion blow molding processes. Our machinery comprises 10 extrusion blow molding plants... -

Product Customized industrial packaging. From concept to volume production.

Whatever you require − an individual component or a complete module, assembled by hand or in-line − you can benefit from our many years of experience and our extensive know-how in the development, industri-alization and production of plastic components of every kind. Our spacious and flexible manufacturing...

Fischer Söhne AG resources (2)

-

News Excellent packaging solutions for Covid vaccine containers and injection vials

COVID-19 is keeping the world in suspense. Around the globe, people are hoping for rapid solutions from the pharmaceutical and medical industries. Demand for accessories such as pharmaceutical packaging has also risen rapidly. The traditional Swiss company Fischer Söhne AG offers corresponding top-quality products.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance