COUNTEC Group/PNF SOFTGEL

About COUNTEC Group/PNF SOFTGEL

Categories

-

KR

-

2022On CPHI since

-

100 - 249Employees

Company types

Meet us at

CPHI Milan 2024

Fiera Milano, Italy

08 Oct 2024 - 10 Oct 2024

Products from COUNTEC Group/PNF SOFTGEL (4)

-

Product Softgel Encapsulation Machine, SE100

-Easy to install and detach system for cleaning-4 lubrication boxes to prevent cross-contamination

-Automatic gelatin thickness measuring system

-Automatic gelatin level control system

-Automatic filling weight control system -

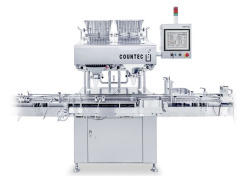

Product Electronic Tablet / Capsule Counter, DMC-120

24 channels with twin filling heads and it is suitable for counting large number at fast speed Up/down dive-in nozzles with adjustable stroke frequency ensure to escaping tablets and no block-age of large tablets. -

Product Electronic Tablet / Capsule Counter, DMC-60T

12 channels with twin filling heads and it is adjustable for counting small number. Advanced functions including tablet shutter time check, dark & light time control, self-compensating vibrator control and sequential shutter closing movement are provide for ease of operation. -

Product Table Top Counter, DMC-4

4 channels with twin filling head and require manual bottle loading and uploading for filling. By the movement of damper cylinder it fills tablet from A site to B side turn by turn.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance