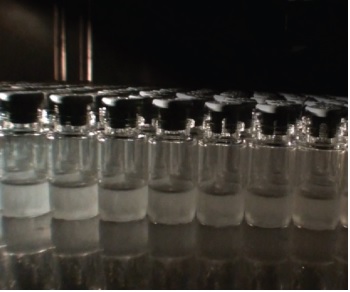

Ensuring robust lyophilization scale-up

Presentation provides new data regarding the mechanism of the ControLyo Technology.

SP Scientific announces the on-demand popular webinar by Jake Luoma of Genentech that discusses how controlled nucleation has emerged as a technology that promises improvements in lyophilization process throughput and consistency.

In this presentation, Mr Luoma examines the benefits of the technology for high fill-volume configurations and presents new data regarding the mechanism of the ControLyo Technology. The presentation shows how gaining a more complete understanding of the mechanism of nucleation using ControLyo Technology ensures more robust freezing when scaling from the lab to commercial-scale freeze dryers.

Traditionally in lyophilization cycles, the freezing process is uncontrolled because of the random nature of the nucleation or crystal-forming process within individual vials and across vials in a freeze dryer chamber. SP Scientific's proprietary ControLyo technology, utilizes pressurization to induce nucleation while maintaining the temperature to within 1 °C of a product’s freezing point and at the same time minimizes the supercooling effect. This produces lowered product resistance with resulting benefits that include improved product uniformity, quality and yield, and depending on formulation a reduction of cycle times by as much as 40%. In contrast to other controlled nucleation techniques, ControLyo Technology process does not introduce any foreign elements which could potentially become a carrier for micro-organisms being introduced into the product vials during the freezing process.

Jacob (Jake) Luoma has been an engineer at Genentech since 2012. After he graduated from the University of Colorado Boulder with a BS in Chemical and Biological Engineering, he joined the Genentech Process Development Rotation Program. Jake then joined the Pharmaceutical Processing and Technology Development group. There, he works on a team which develops pharmaceutical drug product manufacturing processes and technologies on the pilot scale and conducts technology transfers to implement on the manufacturing scale.

Related News

-

News Eli Lilly gets ready to launch five new drugs in 2023

Eli Lilly, the American pharmaceutical company (IN, USA) are gearing up for a big year ahead, with hopes to launch five new drugs and capitalise on growing obesity and Alzheimer’s disease markets. -

News Amgen buys Horizon for $27.8 billion in bold step into the rare disease market

Amgen Inc buys pharmaceutical company Horizon Therapeutics in a multibillion-dollar deal, in hopes to capitalise on it's portfolio of drugs in the highly sort after rare disease market. -

News Pharma Supply Chain People Moves

The latest appointments and promotions across the pharmaceutical supply chain. -

News Merck to donate new Ebola vaccine to defend against outbreaks in Uganda

Pharmaceutical giant Merck has announced they will be speeding up the processing of a new vaccine against the latest strain of the Ebola virus, to be donated to a global non-profit organisation for distribution -

News CPHI Podcast Series: Driving innovation with pharmaceutical startups

The latest episode in the CPHI Podcast Series explores how startups are driving innovation by taking high-risk approaches and doing business with greater agility. -

News Greener and efficient processes: Quaternary Ammonium Salts

Quaternary Ammonium Salts play a crucial part in Organic Chemistry processes at many major industries. Discover why.

-

News Biosimilars save patients $11B annually, but barriers to adoption remain in US market

Biosimilars introduce competition into the biologics market, driving down prices and increasing patient access. -

News WHO recommends use of two monoclonal antibody treatments against Ebola

The health body recommended use of treatments by Regeneron and Ridgeback Bio

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)