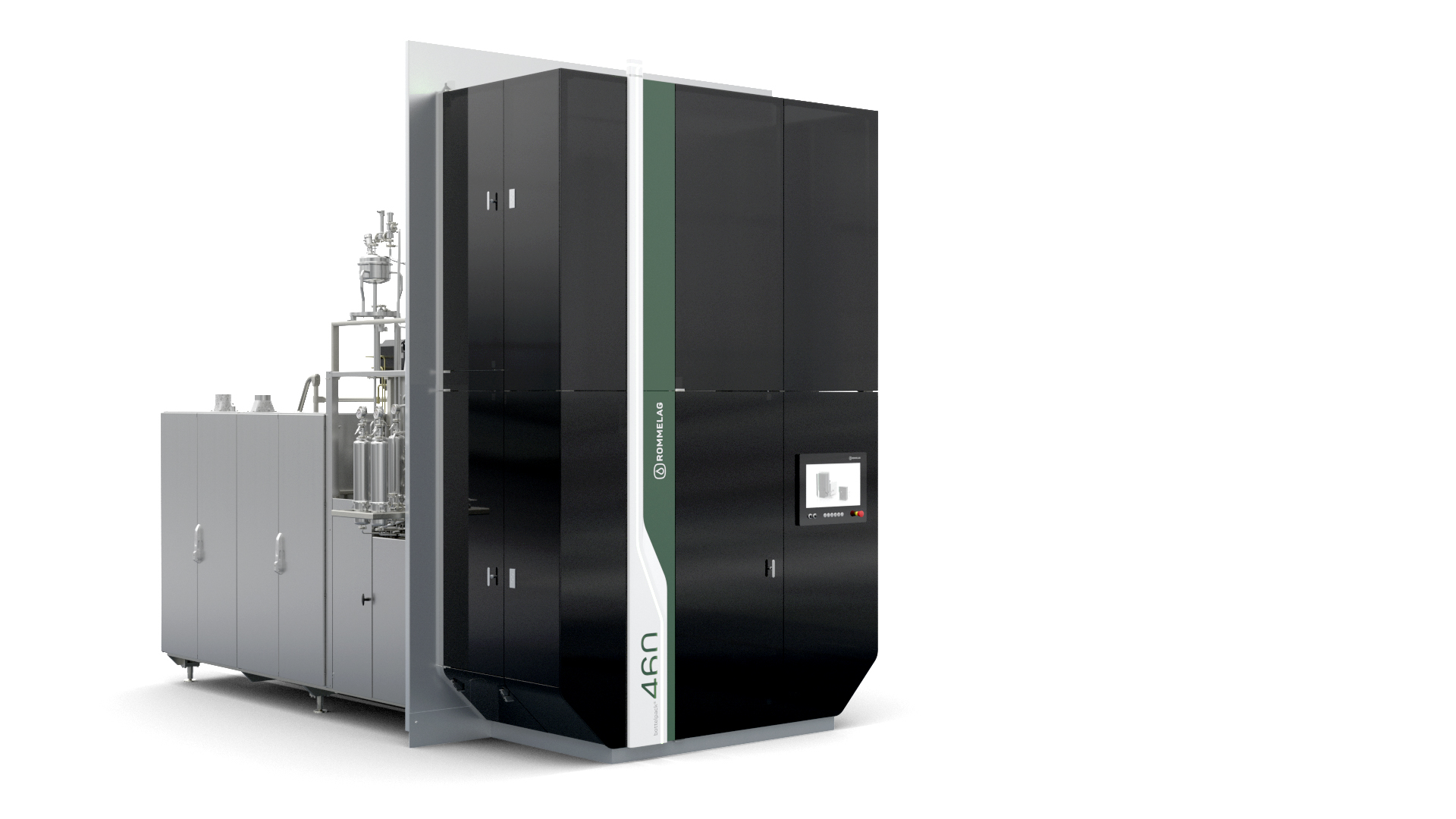

high capacity aseptic filling - bp 460

Product Description

Rommelag

-

CH

-

2018On CPHI since

-

2Certificates

-

1000 - 4999Employees

Company types

Primary activities

Categories

Specifications

Rommelag

-

CH

-

2018On CPHI since

-

2Certificates

-

1000 - 4999Employees

Company types

Primary activities

More Products from Rommelag (2)

-

Product Aseptic Blow-Fill-Seal packaging machine for the production of bottles - bp 321

IV solutions are basic life-saving drugs that are as wide ranging as their applications, including hydration agents, chemotherapy, pain management, antibiotics, plasma volume expanders, total parenteral nutrition, and many more. The blow-fill-seal process offers the highest level of sterility assur... -

Product Aseptic Blow-Fill-Seal packaging machines for the production of ampoules

Not only do bottelpack machines offer cost-effective eye drop production under highly sterile conditions, this method of aseptic filling and packaging also enables flexible container design, a reduced environmental footprint, and preservative-free formulas. Because single-use (also known as unit-...

Rommelag resources (1)

-

Brochure Blow-Fill-Seal Solutions

If it says “bottelpack” on it, you can rely on the uncompromisingly good quality offered by the inventor of blow-fill-seal technology. With a combination of German engineering expertise and Swiss precision, we make sure that your machine only ever produces precisely what you defined – from the smallest ampoule to the largest container. And that’s a promise! Rommelag’s bottelpack machines are capable of manufacturing up to 34,000 containers an hour in a wide variety of forms and plastic blends. Classic container volumes range from less than 0.1 ml to more than 1,000 ml. ml. Sounds good, you say? That’s what our customers say, too, and they enjoy the flexibility, precision, reliability, and virtually unlimited scope of BFS technology.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance