IV & PHARMACOLOGICAL APPLICATIONS

Product Description

Renolit Nederland B.V

-

NL

-

2015On CPHI since

-

1Certificates

-

1000 - 4999Employees

Company types

Categories

Renolit Nederland B.V

-

NL

-

2015On CPHI since

-

1Certificates

-

1000 - 4999Employees

Company types

More Products from Renolit Nederland B.V (10)

-

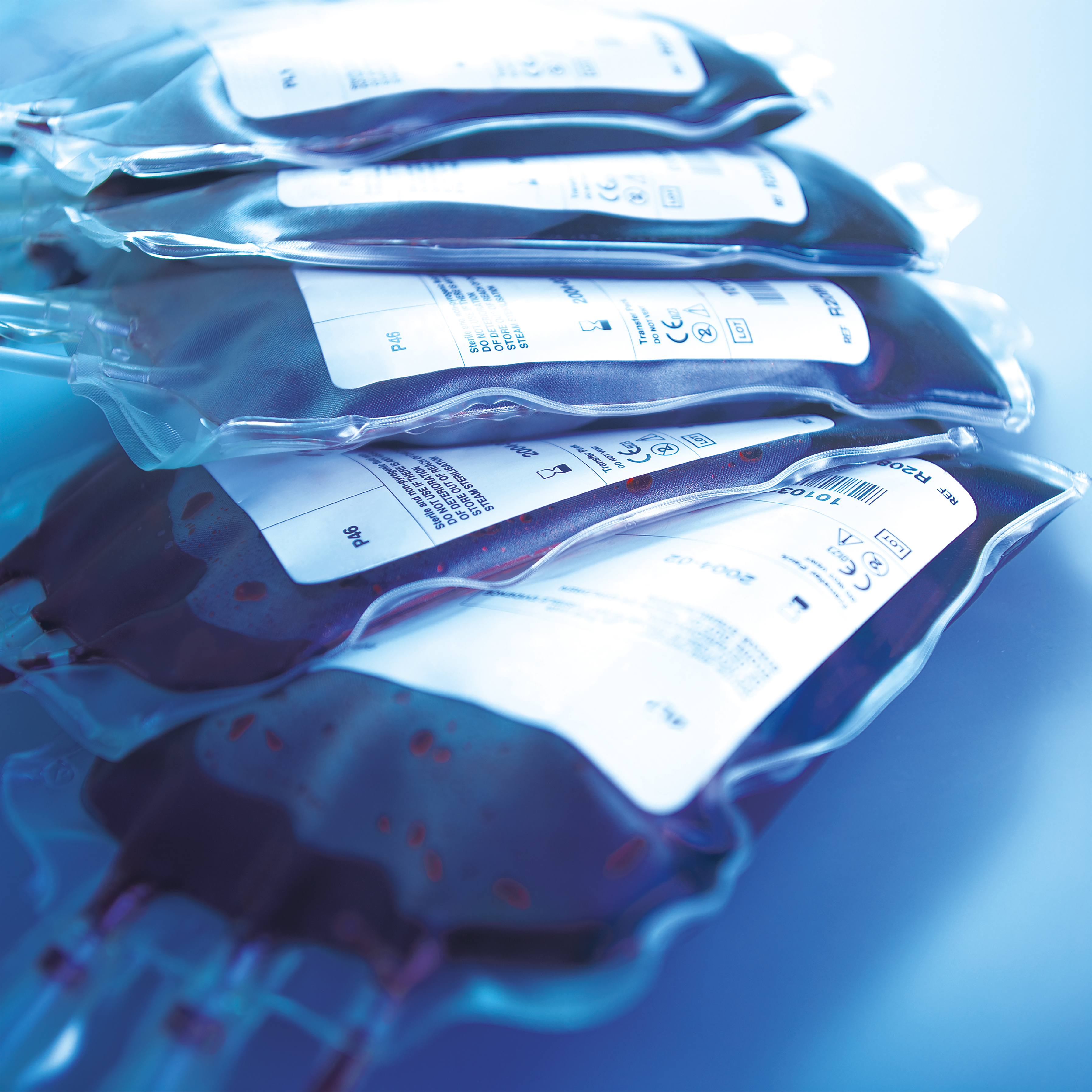

Product BLOOD & BLOOD COMPONENTS

The packaging of blood and blood components is known to be one of the most critical applications of polymer medical films. The developments are frequent and the requirements are increasing every day.

RENOLIT Healthcare is the worldwide market leader for the basic materials for the manufact... -

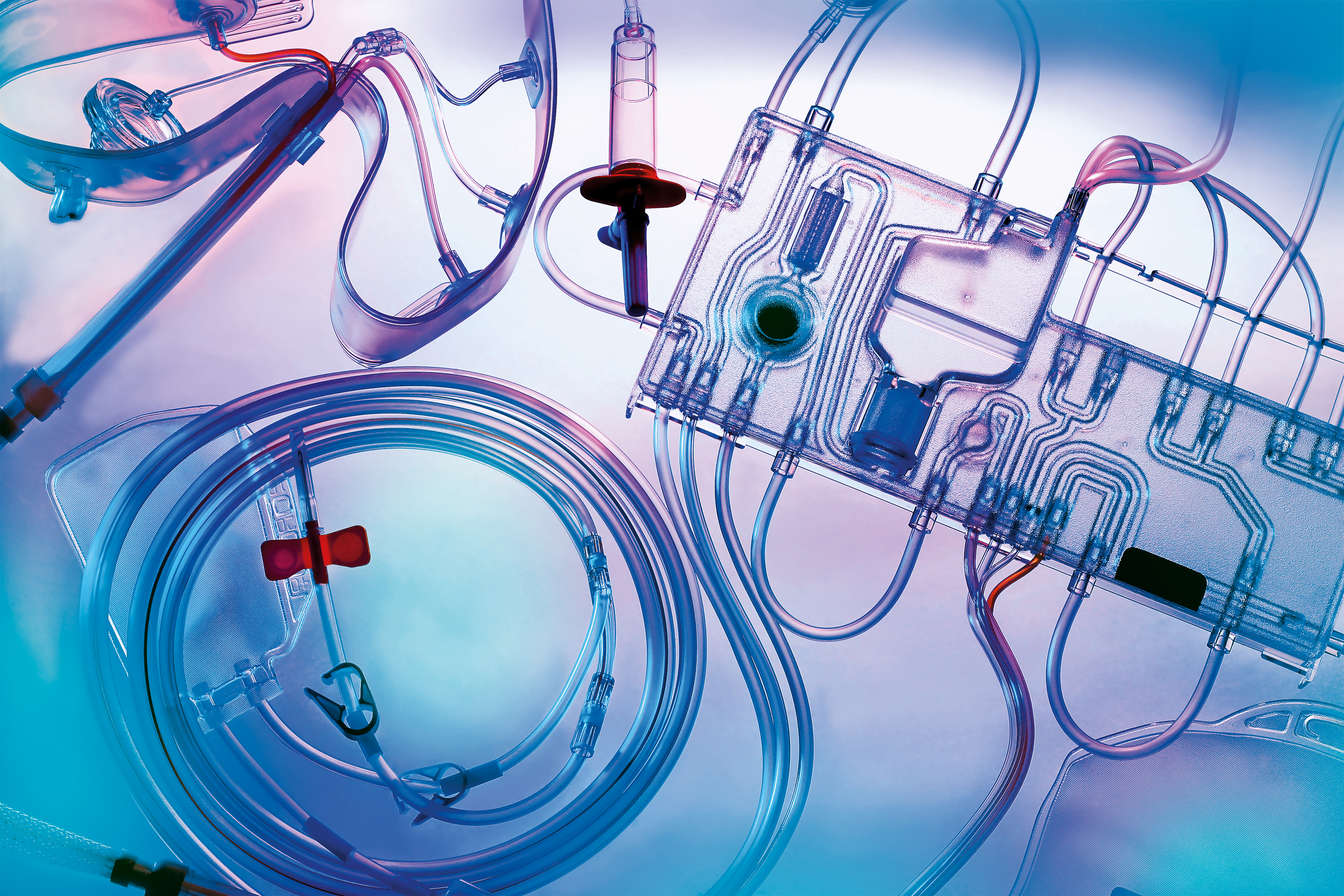

Product BIOTECHNOLOGY

The biotechnology sector is one of the application areas where continuous and frequent developments result in higher material requirements.

Today, flexible polymer single-use systems are replacing traditional glass and stainless steel in applications like meida storage bags, bioreactors, mixing vess... -

Product DIALYSIS

One of the largest application areas for RENOLIT Healthcare products is dialysis. Our materials play an important role here and together with partners we are working on the development of the next generation of dialysis systems.

For renal intensive care treatments, multi-compartment polypropylene ba... -

Product NUTRITION

Total Parental Nutrition (TPN) is required when a patient's demand for macro- and micronutrients cannot be covered by regular or oral enteral nutrition. Let's collaborate to innovate TPN systems with advanced features in many terms.

RENOLIT Healthcare PP and EVA films are used for the storage of lip... -

Product SECONDARY PACKAGING

To ensure the best protection and quality, RENOLIT Healthcare offers co-extruded multilayer polyolefin films for the overwrapping of sterile solution bags and blood bag systems.

SECONDARY PACKAGING

RENOLIT WRAPFLEX films are PP based films designed for the overwrapping/ outer packaging of sterile... -

Product PORTS & CAPS

The production of flexible bags or plastic bottles for intravenous solutions requires specially designed ports and caps. We offer a large variety of high quality components for automated form-fill-seal and blow-fill-seal machines.

For flexible bags for intravenous systems we propose polypropylene po... -

Product SERVICES

With a wide range of new customer services, you will find in RENOLIT Healthcare a strong partner with innovative and customised full-service solutions to meet your specific challenges.

Whether as part of a joint venture or in the form of a partnership - as a service partner RENOLIT Healthcare provid... -

Product EXTRUSION MODELING TECHNOLOGY

Our new EM-Technology allows the development of the next generation of ultra thin multi-layer films with previously unseen combinations of properties such as improved gas barrier, higher puncture resistance and advanced flexibility. This technology improves product properties while significantly reducing r... -

Product CIRCULAR CARBON MANAGEMENT

We are constantly exploring new possibilities to enable future viable solutions for the healthcare sector. We strive to minimise our carbon footprint by improving recycling processes and undertaking research into sustainable materials and resource saving production cycles. -

Product RENOLIT Healthcare worldwide

With 5 global production sites, we offer back-up production for our key products if required by our clients. This way, challenges at one site don't hamper agreed delivery terms. We are also at your service at your production facilities to optimise your processes.

Renolit Nederland B.V resources (3)

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance