Romaco: System Solution with Patented In-Line Scale

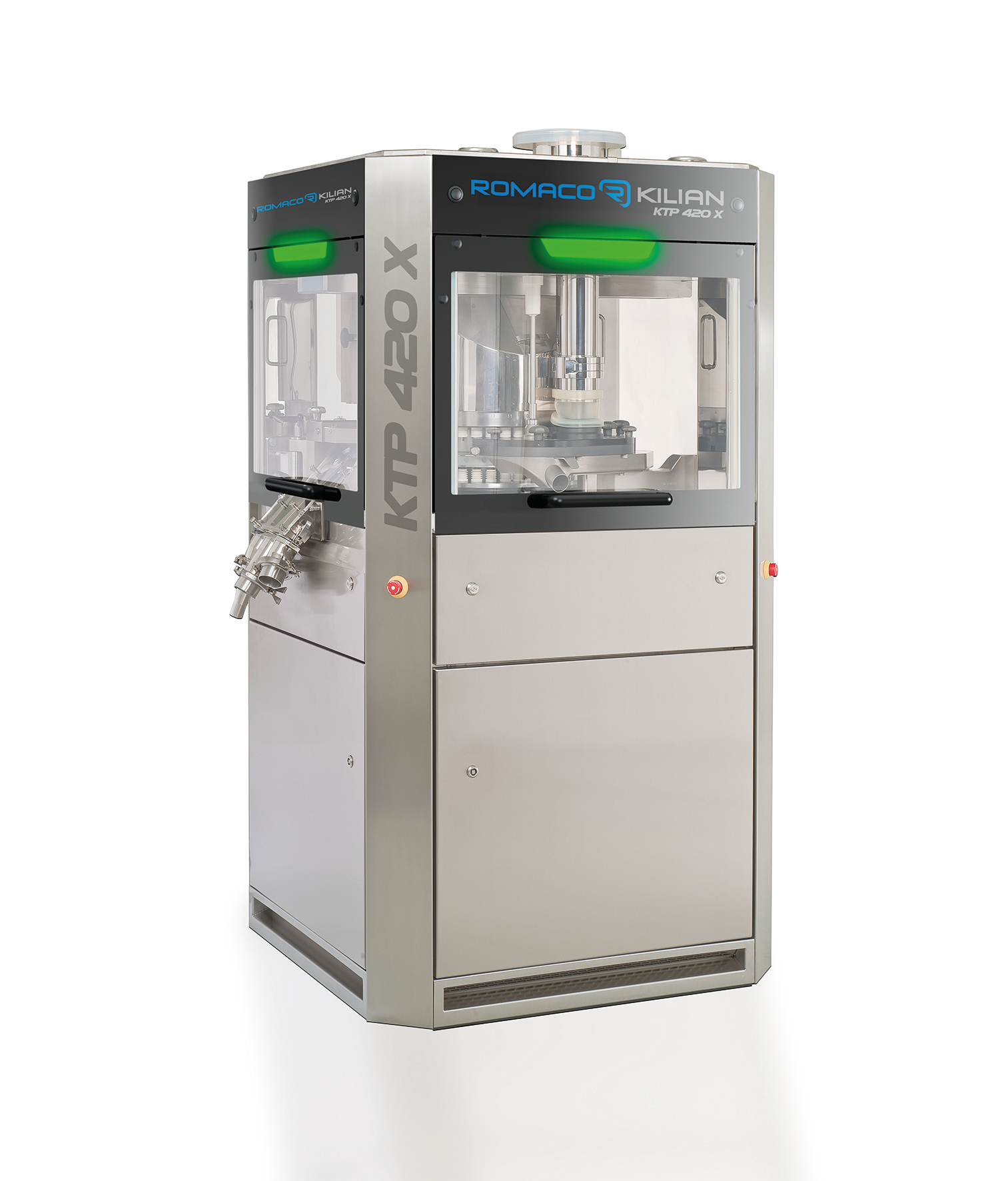

At the forthcoming POWTECH 2014, Romaco Kilian will show the Kilian KTP 420X tablet press with the patented in-line continuous weight control (CWC). The engineering specialist’s new KTP 420X series is an innovative generation of flexible, high speed tablet presses for the pharmaceutical industry.

The Romaco Kilian KTP 420X is a versatile, high speed tablet press which, in combination with the new CWC system, will be Romaco’s highlight at this year’s POWTECH. This groundbreaking machine, equipped with numerous patented features, compresses up to 360,000 tablets an hour. The Kilian KTP 420X is ideal for the production of mono-layer, bi-layer or core tablets (tab-in-tab), and it can also be used to process poorly flowing materials. It is characterised by high effective availability, low costs for maintenance and spare parts and very simple handling. The Kilian KTP 420X is winner of this year’s iF Award for innovative design.

Patented Features

The patented CWC in-line scale allows the weight of the tablet being produced to be measured continuously at the discharge as the products are pressed without destroying them. The KTP 420X makes Romaco Kilian the first manufacturer worldwide to offer a solution for continuous weight control. The weighed tablets are placed in the “good” channel using compressed air. As a result of the new process, there is no longer any need to make sample tablets to check the weight and product loss is reduced to zero. This automatic weight control system helps to avoid unnecessary costs, especially when processing expensive (active) ingredients.

One tablet is measured per turret revolution with an accuracy of 0.1 mg. The CWC system is fully integrated in the PLC and operated over the HMI (human machine interface) panel. The results of the measurements can be leveraged directly to control the machine and greatly improve the reliability of the process. CWC can be supplied as an option for all models in the KTP 420X and KTP 720X series and is also available as a retrofit kit.

High Flexibility and Low Total Cost of Ownership

The wear-free torque motor, extremely durable compression rollers and wear-free lower punch brakes with patented magnets underlie the very low total cost of ownership. The likewise patented punch bellows protect the tablets from lubricants. Thanks to the hermetic separation of the compaction and service areas, no product or oil gets into the machine compartment of the press. The optimised hygienic design permits quick and easy cleaning. At the same time the new, ergonomic, Windows 7 based HMI panel guarantees reliable handling. The significant reduction in press noise adds to the user friendly working environment.

Related News

-

News Eli Lilly gets ready to launch five new drugs in 2023

Eli Lilly, the American pharmaceutical company (IN, USA) are gearing up for a big year ahead, with hopes to launch five new drugs and capitalise on growing obesity and Alzheimer’s disease markets. -

News Amgen buys Horizon for $27.8 billion in bold step into the rare disease market

Amgen Inc buys pharmaceutical company Horizon Therapeutics in a multibillion-dollar deal, in hopes to capitalise on it's portfolio of drugs in the highly sort after rare disease market. -

News Pharma Supply Chain People Moves

The latest appointments and promotions across the pharmaceutical supply chain. -

News Merck to donate new Ebola vaccine to defend against outbreaks in Uganda

Pharmaceutical giant Merck has announced they will be speeding up the processing of a new vaccine against the latest strain of the Ebola virus, to be donated to a global non-profit organisation for distribution -

News CPHI Podcast Series: Driving innovation with pharmaceutical startups

The latest episode in the CPHI Podcast Series explores how startups are driving innovation by taking high-risk approaches and doing business with greater agility. -

News Greener and efficient processes: Quaternary Ammonium Salts

Quaternary Ammonium Salts play a crucial part in Organic Chemistry processes at many major industries. Discover why.

-

News Biosimilars save patients $11B annually, but barriers to adoption remain in US market

Biosimilars introduce competition into the biologics market, driving down prices and increasing patient access. -

News WHO recommends use of two monoclonal antibody treatments against Ebola

The health body recommended use of treatments by Regeneron and Ridgeback Bio

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)