SRL Secoya Technologies

About SRL Secoya Technologies

Categories

-

BE

-

2020On CPHI since

-

1 - 24Employees

Company types

Products from SRL Secoya Technologies (3)

-

Product Continuous Crystallization Technology

Production equipment for a controlled crystallization process.

Through the use of small diameter capillaries, the crystallization tool of Secoya is able to master supersaturation conditions and control the nucleation process. By precisely selecting parameters, the nucleation rate can be adjusted to ... -

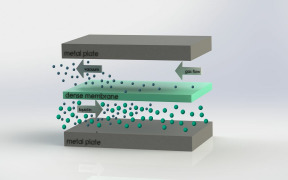

Product Pervaporation Technology

Pervaporation is a liquid/liquid separation process using a selective and dense membrane.

By creating a vacuum or introducing a flow of purge gas on one side of a dense membrane, volatile compounds in the liquid present on the other side will selectively diffuse through the membrane.... -

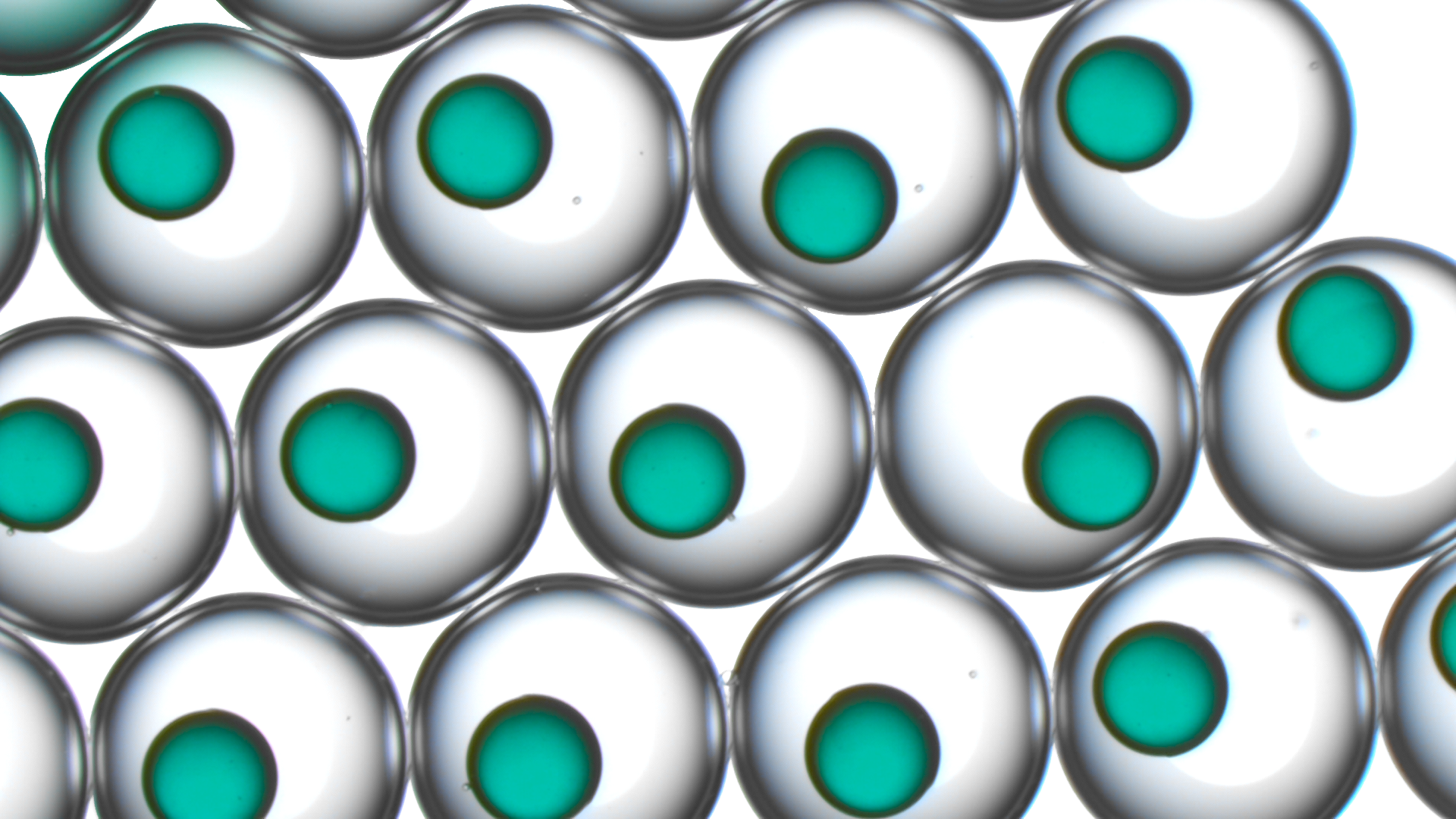

Product Emulsification and Encapsulation Technology

On the basis of microfluidic principles, Secoya develops and supplies a novel emulsification technology – RayDrop®- for the production of monodispersed droplets or particles.

The emulsification process in the RayDrop® is based on co-flow and flow-focusing technologies embedded in a ...

SRL Secoya Technologies Resources (1)

-

Video How Secoya Technologies can help you in your process development activities.

A brief overview of the problems in pharmacetucial production industry where Secoya Technologies can provide solution.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance