The Schur®StarLight Machine

Product Description

Schur Star Systems GmbH.

-

DE

-

2018On CPHI since

-

100 - 249Employees

Company types

Categories

Specifications

Schur Star Systems GmbH.

-

DE

-

2018On CPHI since

-

100 - 249Employees

Company types

More Products from Schur Star Systems GmbH. (2)

-

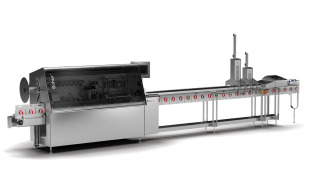

Product Schur®Star Packaging Machine

Schur®Star Systems offer the most flexible packaging solution available. The Schur®Star Concept consists of the Schur®Star packaging machine and the pre-made Schur®Star bags supplied to our customers linked together on a unique string.

It sets the stage for increased marketing options, improved ... -

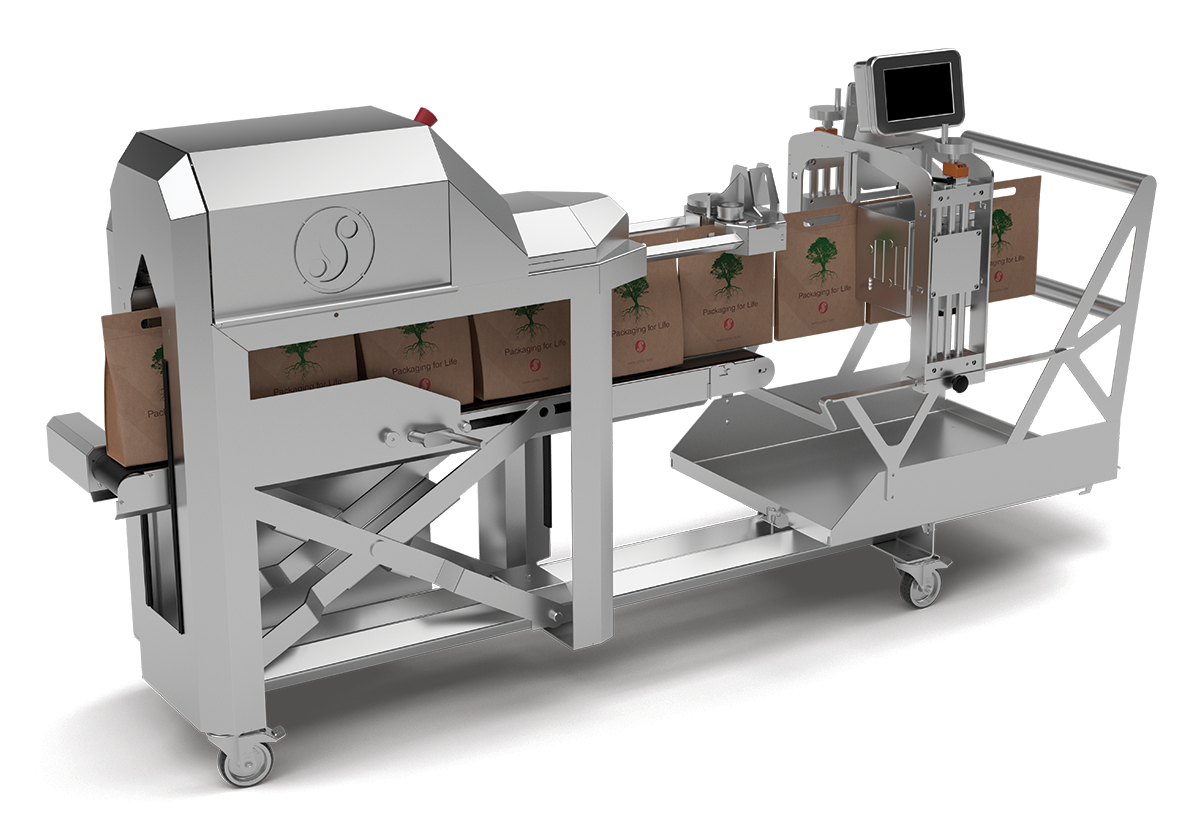

Product Schur®Star Bag in Bag

The Schur®Star Bag in Bag ensures product integrity and hygiene levels.

The concept of premade bags ensures a pure, consistent and safe packing process, the bags remain closed from bag production until filling.

The fully automatic bagging process provides safe and hygienic sealing after fill...

Schur Star Systems GmbH. resources (2)

-

News Double or triple bagging of sterile products - fully automated with the Schur®Star Concept

Double or triple bagging of pharmaceutical items is required when their final point of use is an operation theatre or another vulnerable area, requiring extreme hygiene measures. The product could be trigger sprays containing IPA or ethanol liquids, where the bags are removed stepwise along being transported to the final point of use. -

Video The Schur®Star Concept - Double & triple bagging technology

Manual handling could never match the consistent and precise workflow of a fully automated process on a Schur®Star Packaging Machine. The concept of pre-made bags offers a precise and consistent bag intake ensuring that the bag will always be placed meticulously correctly for the filling process. Integrated robots collect and insert the products precisely into the bag – both single and double index filling - and fold the bag top down. Integrated air evacuation units do likewise handle these steps fully automatically. Also irradiation dots can be placed automatically onto the bags for added peace of mind. And only one operator is required to keep an eye on the control panel and continuously providing product supplies to the conveyor.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance