Whitepaper Design for manufacturing

Product Description

IGS GeboJagema

-

NL

-

2017On CPHI since

-

1Certificates

-

100 - 249Employees

Company types

Primary activities

Categories

Specifications

IGS GeboJagema

-

NL

-

2017On CPHI since

-

1Certificates

-

100 - 249Employees

Company types

Primary activities

More Products from IGS GeboJagema (3)

-

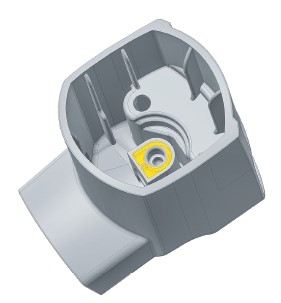

Product Moulds For Drug Delivery Devices

IGS GeboJagema offers moulds for drug delivery devices. Features: it is available from metered dose inhalers and insulin pens to dose counters. Contact us for more information. -

Product Moulds for Drug Delivery Devices

Moulds for Auto Injectors, Insuline Pens, Pre filled Syringes -

Product High Precision Moulds; Pilot, Pré-production, Industrialization, Duplicate, Project Tooling (10 or more moulds simultaneously for 1 device)

Who we are: As a medical company, you may have a great idea for a device that will give you a competitive edge.But first you have to find a way to manufacture it according to the strict regulatory requirements for medical devices. IGS GeboJagema can help. For over 70 years, we have been delivering high pre...

IGS GeboJagema resources (6)

-

News IGS GEBOJAGEMA PROJECT MANAGEMENT OF 10 OR MORE COMPONENTS - MOULDS NEEDED FOR ONE DRUG DELIVERY DEVICE

IGS GEBOJAGEMA can handle 10 or more moulds needed for one new Drug Delivery Device -

Whitepaper Green Mould

Enabling sustainable injection moulding. The efforts to combat climate change will havea huge impact on the world economy over thenext decade and beyond. Greenhouse gasemissions must be reduced dramatically. TheEU is aiming at a reduction of 55% by 2030,compared to 1990 levels.* Similar goals arebeing set both by countries and companies inthe rest of the world.To achieve reductions of this magnitude, all sectors andindustries must investigate ways to do more with less. Thisapplies to all companies involved in injection mouldingas well. Traditionally, the critical factors for moulds havebeen accuracy, cycle time, reliability and maintenancefriendliness.But as the world takes steps towards a carbonneutral economy, we expect that energy usage will becomeincreasingly important. -

News IGS GEBOJAGEMA Company Movie

Our problem-solving mindset, proven track record in the healthcare industry, considerable medical experience and meticulously methodical way of working ensures you the highest quality, process control and traceability needed for your medical products. -

News IGS customer reference project; Actuator, Dose Counter - Dose Indicator

Who we are

As a medical company, you may have a great idea for a device that will give you a competitive edge.But first you have to find a way to manufacture it according to the strict regulatory requirements for medical devices. IGS GeboJagema can help. For over 70 years, we have been delivering high precision moulds for some of the most successful metered dose inhalers, insulin pens, diagnostic products and other medical devices in the world.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance