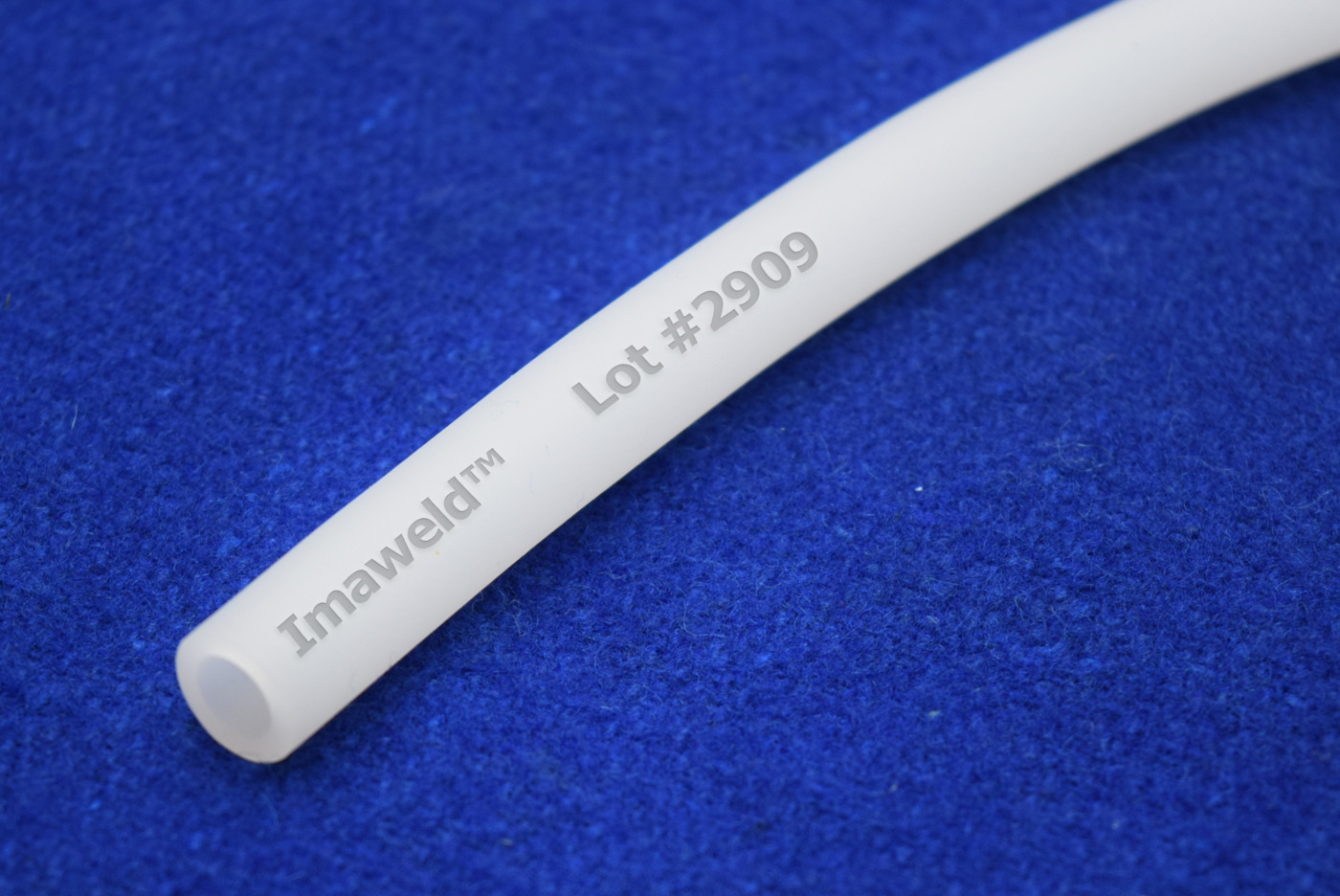

Imaweld® - Heat Sealable Thermoplastic Elastomer Tube

Product Description

Ami Polymer Pvt. Ltd.

-

IN

-

2015On CPHI since

-

3Certificates

-

250 - 499Employees

Company types

Categories

Specifications

Ami Polymer Pvt. Ltd.

-

IN

-

2015On CPHI since

-

3Certificates

-

250 - 499Employees

Company types

More Products from Ami Polymer Pvt. Ltd. (25)

-

Product EPDM Self Adhesive Strip Gasket

Advantage of EPDM self Adhesive Strip:

Easy to install, just peel off the self adhesive backing. The adhesive backing tape used is not fully resistance to water, therefore where there is a large amount of moisture or water present; it is advisable to use plain expanded EPDM a good conduct adhe... -

Product Imapex® - Peroxide Cured Silicone Transparent Tube

Imapex® peroxide grade silicone tubing is designed for general, non critical applications. Imapex® is translucent silicone tubing having good flexibility and resiliency. It is suitable for peristaltic pump applications for non critical fluid transfer.

Imapex® Ch... -

Product Imavacfit® - Platinum Cured Silicone Hose reinforced with Polyester Braiding and SS 316 Helical Wire

Imavacfit® is platinum cured silicone hose reinforced with SS 316L helical wire and polyester braiding having better flexibility with high pressure resistance. Imavacfit® is having high burst pressure rating along with high vacuum resistance compare to Imavac™. The product is suitabl... -

Product Sifter Sieves

A sieve or sifter, is a device for separating wanted elements from unwanted material or for characterizing the particle size distribution of a sample, typically using a woven screen such as a mesh.Sifting is mainly used in two areas, Check screening of raw material to remove extraneous material and Sizing ... -

Product Silicone Bellow

With the support of talented professionals, we are passionately engaged in offering high quality Silicone Bellow. Widely demanded in the industry, the offered bellow is highly used for protecting machine parts from dust and corrosion. Keeping in mind the varied requirements of our precious clients, we make... -

Product Imapure®- Platinum Cured Silicone Transparent Tube

Imapure® is Platinum Cured Silicone Tubing designed for peristaltic pump and fluid transfer in Pharmaceutical and Biotech applications. Imapure® is translucent silicone tubing known for its ultra smooth bore to prevent any particle entrapment. It is especially designed to comply with require... -

Product Imafit® - Platinum Cured Silicone Hose reinforced with Polyester Braiding

Imafit® is platinum cured silicone hose reinforced with polyester braiding. It has excellent flexibility for pressurized fluid transfer application in pharmaceutical and biotech industries. We are catering these products to all pharma and biotech companies in India as well as Overseas market. Im... -

Product Imawrap® - Platinum Cured Silicone Hose reinforced with 2 to 3 Ply pf Polyester Fabric and SS 316 Helical Wire

Imawrap® is platinum cured silicone hose reinforced with SS 316L helical wire and 2-3 layers of polyester fabric wrapping. Imawrap® is having multiple layers of high quality polyester fabric to enhance burst pressure rating. The product is suitable for high pressurized steam transfer app... -

Product Imaseal® - Silicone Inflatable Gaskets & Seals

Imaseal® is made from advance grade silicone rubber conforms to FDA 21 CFR 177.2600 for food grade criteria suitable for various sealing applications. These inflatable seals starts inflation range from 5mm to 20mm when 2-4 kg./cm2 pressure is applied after installation in door.

Imaseal® ... -

Product Imaprene® - Thermoplastic Elastomer Tube (TPE)

Imaprene® pharmaceutical grade thermoplastic elastomer tubing designed for peristaltic pump transfer. Imaprene® is opaque tubing especially known for its excellent flexibility and flex crack resistance.

Imaprene® Characteristics:

1. Manufact... -

Product Imavac® - Platinum Cured Silicone Hose reinforced with SS 316 Helical Wire

Imavac® is platinum cured silicone hose reinforced with SS 316L helical wire. It has better transparency to visualize flow and kink resistance. Imavac® is designed for material transfer application under high vacuum in pharmaceutical industries. The product is more superior compare to Imafit®... -

Product Imachemton® - Fluoro Elastomer Tube (FKM)

Imachemton® is fluoropolymer tubing (popularly known as Viton tubing) especially designed for highly corrosive chemicals and solvents used in pharmaceutical industries. It is manufactured in dedicated controlled environment to comply critical food and pharma grade standards.

...

Ami Polymer Pvt. Ltd. resources (3)

-

News Single Use Assembly for Biopharmaceuticals Industry

Our Ready to use Single use assemblies have the below features:- Made of tubings, PP connectors (Tri-clovers, Straight connectors, Y/ T/ X connectors), Aseptic Connectors, Filters, Bags, Manifolds etc.

- Manufactured and Packaged in Clean room of Class 10,000

- Gamma irradiated for 25- 45 kGy for SAL Up to 10–6

- Validated for Bioburden, Sterility Assurance Level and USP 788 Particulate testing

-

Video Corporate Video

Ami Polymer Pvt. Ltd. (APPL) was established in 1996 with the aim of being global leaders in field of silicone rubber product solutions to Food, Pharma and Engineering sectors. APPL is having dedicated manufacturing Clean Room facility of class 10000 in Silvassa (DNH) and distribution network in more than 20 countries including UK, USA. 1st Indian silicone product manufacturing company to have TOXIKON based E&L Studies, USP Class VI (USP 87 in vitro) for Platinum Cured Silicone Tubing & NSF-51 Certification. -

News Our New Facility

It is taking immense pleasure to announce about Our New APPL Facility (2,50,000 Sq. Ft. Area), which will be launched by end of the Year 2021 at Silvassa, DNH, India. New facility will be have technologically advanced Clean rooms ( From Class 100 to 100000) with latest extrusion/ Moulding/ Assembling Capacity.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance