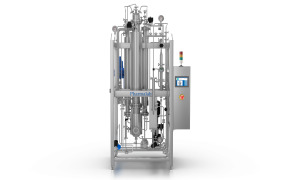

Steam sterilizer

Product Description

Pharmalab India Pvt Ltd

-

IN

-

2015On CPHI since

Categories

Specifications

Pharmalab India Pvt Ltd

-

IN

-

2015On CPHI since

More Products from Pharmalab India Pvt Ltd (29)

-

Product Rotary Bottle Washing Machine

Pharmalab india pvt. Ltd. Offers wide range of products and services which include rotary bottle washing machine. Rotary Indexing Type Bottle Washing Machine is specially designed for the output upto 96 BPM of different sizes of bottles. Machine has provision for 4 types of internal and one external washes... -

Product Linear Bottle Washing Machine

Pharmalab india pvt. Ltd. Offers wide range of products and services which include linear filling machines. We have dedicated our engineering capabilities and expertise for developing high speed machines to meet the industry needs. Contact us for more information. -

Product Automatic liquid filling machine (linear)

Pharmalab india pvt. Ltd. Offers wide range of products and services which include automatic liquid filling machine (linear). Machine is designed to fill various types of liquid in various types of containers. Machine works on volumetric principle. Adjusting the displacement of piston can set a fill volume... -

Product Monoblock filling and sealing machine

Pharmalab india pvt. Ltd. Offers wide range of products and services which include monoblock filling and sealing machine. Pharmalab’s Monoblock is fitted with Filling & Sealing heads on a single base having common drive assembly to improve efficiency of filling & Sealing. The machine is suitab... -

Product Pure steam generator

Pharmalab india pvt. Ltd. Offers wide range of products and services which include pure steam generator. It consists of shell and tube heat exchangers where heat transfer is done by falling film evaporation which gives assurance for achieving high temperature for every drop of water, assures the sterility ... -

Product WFI Generation Plant

Over the last 30 years, Pharmalab has been the leading supplier of plants producing water for injection, which meets international standards, including USP, IP, BP and JP. The plants are manufactured as per FDA’s current Good Manufacturing Practices (cGMP) and ASME requirements and follows the basic princi... -

Product Steam sterilizer (hinged door)

Pharmalab india pvt. Ltd. Offers wide range of products and services which include steam sterilizer (hinged door).

Our sterilizer has been engineered to meet the stringent manufacturing standards, like cGMP, EN285 (European), MHRA (UK), FDA (US), being followed by the Pharmaceutical & Bio-te... -

Product Pure steam qualtiy test kit

Pharmalab india pvt. Ltd. Offers wide range of products and services which include pure steam quality test kit. Pure Steam Quality plays a vital role in steam sterilization of load in Pharmaceutical Industry. International regulatory standards such as EN 285, EN 17665 & HTM2010 recomends steam qua... -

Product Rubber stopper processor cum sterilizer

Pharmalab india pvt. Ltd. Offers wide range of products and services which include rubber stopper processor cum sterilizer. Pharmalab’s unique Bung Processor along with a sterilizer enables customers to reap benefits of ‘twin processes’ from single machine.The bungs are loaded into a ‘drum’ and later ... -

Product Ventilator sterilizer - air and steam mixture

Pharmalab india pvt. Ltd. Offers wide range of products and services which include ventilator sterilizer - air and steam mixture. Use: it is used in sterilization of filled containers of hdpe / ldpe, multi-layer pouches / bottles & glass bottles. Air & steam mixture (Ventilator) terminal steri... -

Product Super heated water spray sterilizer

Pharmalab india pvt. Ltd. Offers wide range of products and services which include super heated water spray sterilizer. Use: it is used in sterilization of filled containers of hdpe/ldpe bottles, pvc multi-layer pouches or glass bottles. Certain products need to be sterilized in its final cont... -

Product Dry heat sterilizer

Pharmalab india pvt. Ltd. Offers wide range of products and services which include dry heat sterilizer. It is used for complete destruction & removal of all micro-organisms by means of dry heat. Use: it is used in glass bottles, vials, ampoules, containers. Contact us for more information.

Pharmalab India Pvt Ltd resources (1)

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance