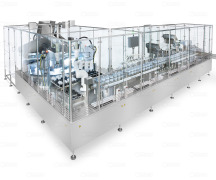

SX-220-PP

Product Description

Dara

-

ES

-

2015On CPHI since

-

250 - 499Employees

Company types

Specifications

Dara

-

ES

-

2015On CPHI since

-

250 - 499Employees

Company types

More Products from Dara (4)

-

Product Filling & Closing machine

High speed filling and closing machines for large volume parenteral solutions.100% weight control / Filling from 0.1 ÷ 1.050 ml. / Output up to 24,000 uph. / Conforms with cGMP - US FDA. -

Product HSL-VS VIALS + SYRINGES

The equipment we present is a high speed compact filling & closing machine for combined automatic processing of vials & single-use syringes, for all kinds of liquids, semi-liquids or powder, in sterile conditions.Single-use of syringes have quickly become the preferred format of pharmaceutical appl... -

Product HSL-LYO ASEPTIC FILLING

High speed filling and closing machines for injectable and lyophilized vials.Dosing control of 100% of vials / Filling from 0.1 ÷ 250 ml. / Output up to 24,000 uph. / Conforms with cGMP - US FDA.

The equipment we present is a compact filling and closing machine for automatic processing of cylindrical vi... -

Product SX-310-PP

Compact machine for automatic infeed, filling, and closing of injection vials.Filling from 0.1 ÷ 250 ml. / Filling system 100% weight control / Output up to 7,200 uph. / Conforms with cGMP - US FDA.

The equipment we present is a compact filling and closing machine for automatic processing of cylindrical...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance