14C Radiolabelling

Product Description

Almac Group

-

GB

-

2015On CPHI since

-

4Certificates

-

5000+Employees

Company types

Primary activities

Categories

Almac Group

-

GB

-

2015On CPHI since

-

4Certificates

-

5000+Employees

Company types

Primary activities

More Products from Almac Group (16)

-

Product Custom and Flow Chemistry

Our continuous flow technology platform enables access to better synthetic strategies which are shorter, offer assured safety, reduce environmental impact and control of by-products. In addition, improved yields and improved reaction selectivity is achievable. With the reaction under tight control, the... -

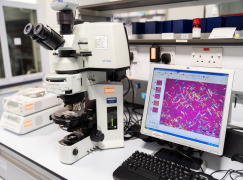

Product Physical Sciences - Preformulation & Solid State Services

Almac's Physical Sciences groups' comprehensive range of services and expertise will help strengthen the success of your product. Identifying and consistently producing a drug in its optimal physical form is vital to any successful drug development programme. It also avoids the need for bridging toxicologi... -

Product Ultra-low Temperature Commercial Solutions

Working collaboratively with our clients, we specialize in providing innovative, tailored solutions supporting advanced therapy (cell and gene) product launches, Just in Time labelling and packaging at ultra low temperatures, QP release and 3PL supply chains. -

Product NeoPeptides(TM)

Our NeoPeptide(TM) experts have been associated with the individualised cancer vaccine field for several years and our MHRA registered facility and systems have been established to enable fully GMP compliant manufacture and release of 20-30 GMP peptides within less than three weeks. A bespoke Pharmaceutica... -

Product Serialisation

Serialisation and Track & Trace Addressing evolving global serialisation legislation, Almac's expert multi-disciplinary serialisation team lead the way in supporting clients in developing their serialisation strategies to GS1 standards. Our Experience Almac have over... -

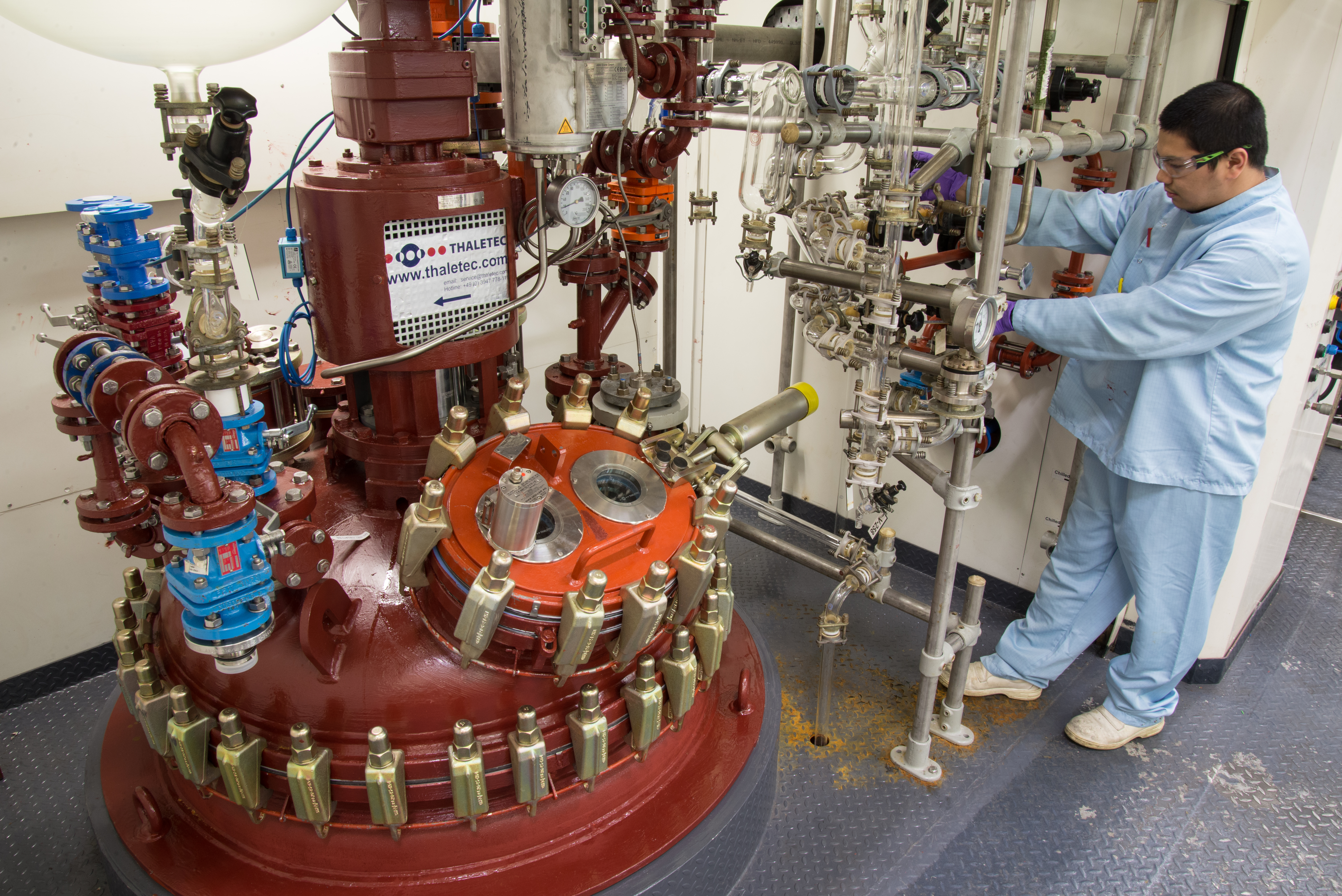

Product API Services, Chemical Development & Manufacture

Almac’s strength in API development and manufacture is proven by being the partner of choice for many pharma and biotech companies seeking integrated drug development solutions from molecule to market.

Our technical expertise and extensive facilities enable us to offer integrated API contract ma... -

Product Analytical Services

With 55+ years of experience, our expert teams develop 1,000+ analytical methods and validate 250+ methods annually. Drawing upon an extensive range of analytical technology, combined with a wealth of analytical knowledge, we can add real value to your drug development and commercialisation programs.... -

Product Biocatalysis Solutions

BBiocatalysts are essential tools in chemical synthesis, particularly in the synthesis of pharmaceutical and fine chemical targets.As highly selective catalysts, they offer a direct and simple way to synthesise complex achiral and chiral compounds. The application of biocatalysts in the pharmaceutical and ... -

Product Commercial Drug Product Manufacture

Over 40 years’ Experience Manufacturing Solid, Oral Dosage Forms

Scaling up from our development services to full scale commercial drug product manufacture or transferring existing commercial products we can meet your commercial drug product manufacturing requirements.

Our range of com... -

Product Commercial Packaging

We offer a wide range of commercial packaging solutions to meet your needs, from initial artwork and pack design, to commercial packaging and distribution.

From our UK and US commercial packaging facilities, we are able to serve global markets. We are MHRA and FDA licensed an... -

Product Commercial Storage and Distribution

Complementing our commercial manufacturing and packaging services, we provide a range of commercial storage and distribution solutions for solid oral dosage forms and sterile biopharmaceuticals, for both niche / orphan drug products and large scale commercial market volumes.

Utilising our bespok... -

Product Peptide and Protein Technology

Almac’s peptide and protein technology offering is a key component within our suite of services. We offer a complete range of peptide and protein services from catalogue products through to GMP manufacture from early phase to commercial launch. We have a proven track record in high quality supp...

Almac Group resources (33)

-

News Almac Sciences awarded Life Sciences Innovative Manufacturing Fund Grant

Grant awarded to support the expansion of Almac’s small molecule API manufacturing plant -

Brochure Think Almac Sciences

Your integrated API and analytical services provider -

News Tonix Pharmaceuticals Announces Selection of Two Contract Manufacturing Organizations for the Launch and Commercial Manufacture of Tonmya™ for the Management of Fibromyalgia

Tonmya™ is a potential new first-line, centrally acting non-opioid analgesic for the management of fibromyalgia, supported by positive results from two Phase 3 studies

New Drug Application (NDA) submission to the FDA planned for second half of 2024

-

Brochure Almac Pharma Services

Tailor-made Pharmaceutical Development & Commercial Solutions -

News Almac Group Expands Commercial Manufacturing and Packaging as well as Peptide Production Capacity at Headquarters with Two New Purpose-Built Facilities

The Almac Group has today announced the completion of two new purpose-built facilities at its headquarters in Craigavon, Northern Ireland meeting client demand in commercial manufacturing and packaging as well as peptide production.

-

Whitepaper Achieving faster formulation of solid oral dosage forms for First-In-Human supplies using drug-in-capsule approach

By Dr Colin Lorimer, Formulation Development Manager, Almac Pharma Services -

News Almac Group opens a new custom-built GMP warehouse at its Global Headquarters

The new custom-built facility will consolidate the existing warehouses to support all manufacturing and laboratory activities. -

Brochure Ultra-Low Temperature Packaging & Distribution Solutions

With more than 50 years’ experience, we offer a wide range of specialised packaging solutions to meet, and deliver your product launch and ongoing commercial needs. -

News Almac Group Wins Life Sciences Team of the Year

Almac Sciences’ Technology Group was selected as the winner of the “Life Sciences Team of the Year” category during this year’s Irish Life Sciences Awards ceremony, held on 6 July 2023 at Crowne Plaza Hotel, Dublin.. -

Brochure Tailor-made Product Launch Solutions

Balancing speed with precision, our flexible suite of offerings provides you with a reliable, effective, and expert approach to support the successful and timely introduction and launch of your new product and market penetration into new territories. -

News Almac Sciences and University College Dublin BROADEN Continuous Flow Chemistry Collaboration

Strengthened collaboration with University College Dublin (UCD) that will focus on the development of novel continuous flow protocols for accessing new industrially relevant drug targets. -

Brochure Almac Pharmaceutical Development

Our product development service spans early to late phase clinical programs, offering technical experience and dedicated project management, and a track record of on-time delivery from state-of-the-art facilities. -

News Almac Group Awarded with Six CDMO Leadership Awards Across all Core Categories

Overall recognition received for compatibility, expertise, quality and reliability. -

Brochure Think Almac...Radiolabelling

Non-GMP & GMP stable & radiolabelling expertise14C labelling of drug substance for human AME studies

Stable & radiolabelled metabolite synthesis

Specialist expertise in peptide & bioconjugate 14C labelling

QC, Analytical & QA integration

MHRA regulatory approved for 14C GMP manufactureof drug substance -

News Almac Group secures HPRA certification for biologics testing

Health Products Regulatory Authority (HPRA) has certified Almac Sciences Ireland (ASI) facility for testing of biologics after a successful audit -

Brochure Think Almac...Superior peptide solutions

Over 30 years’ experience in peptide manufactureRapid throughput, high quality manufacture

Customised supply plan for your project needs

Free consultation on peptide design & manufacturability

Smooth transition to scale-up & cGMP manufacture

Strong emphasis on project management & customercare throughout project lifetime -

News Almac Group Completes First Stage of GMP API Facility Expansion

Expanded GMP manufacturing facility now operational for use in clinical and / or commercial manufacturing -

Brochure Think Almac...Preformulation development

As a world leader in pharmaceutical services, Almac delivers early formulation development workprograms for DRF/PK/tox studies. Designed to maximise solubility and bioavailability withoutcompromising on chemical stability, the studies accelerate drug development to the clinic and minimizerisk in any downstream activities. Almac offer bespoke work packages specifically tailored to thephysiochemical properties of the API (BCS class II, III, or IV) for solubility or permeability enhancement. -

Brochure Think Almac...Crystallisation process development

As a world leader in pharmaceutical services, Almac deliversbespoke crystallisation development work programs for smallmolecules and peptides designed to provide a robust, scaleable,and transferrable crystallisation procedure to help accelerateclinical development and minimise risk in any downstreamactivities by eliminating batch-to-batch variability -

Brochure Think Almac...Solid form screening

As a world leader in pharmaceutical services, Almac delivers unrivalled polymorph,salt, co-crystal, and early crystallisation work programs designed to identify the mostdevelopable solid form of your API to help accelerate development to the clinic andminimise risk in any downstream activities. -

Brochure Think Almac...cGMP peptide manufacture

Expertise in long peptides, radiopharmaceutical precursors & peptide cocktailsSolid phase & liquid phase synthesis

Experience in conjugation to a wide range of chemical entities

Strong project management culture

Full support from in-house analytical & QA teams, & for CMC section preparation -

Brochure Think Almac...Can we help you cure cancer?

Almac can help you achieve success in your cancer research programmes using our range of peptide technologies:• Specialist research reagents

• Peptide conjugates

• Custom peptide synthesis

• Individualised cancer vaccines (NeoPeptidesTM) -

Brochure Think Almac...Integrated flow technologies

Almac has the expertise andcapabilities to deliver flowtechnologies from proof ofconcept reaction validitythrough to manufacture withdefined workflows -

Brochure Think Almac...selectAZyme

Almac’s biocatalysis expertise ranges from enzyme discovery, enzyme engineeringand enzyme production to the synthesis of complex chiral intermediates andactive ingredients, all based on selectAZymeTM technology. Challenge us with yourchemistry problems and see how we can successfully deliver biocatalysis solutionsand more... -

Brochure Think Almac...Integrated enzyme technologies

At Almac we have the expertise and capabilities to deliver enzyme technologies from their discovery through to commercial enzyme supply -

Brochure Think Almac...Analytical solutions for biologics

Providing comprehensive and flexible analytical solutions toaccelerate the development and approval of biologics -

Brochure Think Almac...Analytical Services

Drawing upon our vast pool of scientific knowledge, we greatly reduce the analytical challenges that typically arise during drug development. -

Video Almac Pharma Services

Almac Pharma Services offers early and late phase pharmaceutical development. Its expertise also includes pharmaceutical product launch & distribution, commercial drug product manufacture, commercial packaging, serialisation and commercial storage & distribution. -

Video Almac Sciences

Almac Sciences offers services including API development & manufacture, radiolabelling, biocatalysis solutions, peptides & protein technology, pre-formulation, solid state and analytical services. -

Brochure Commercial Packaging Solutions

We offer a wide range of tailored commercial packaging solutions and global expertise, to meet your product launch (including rapid launch) and commercial needs. -

Brochure Powder in Bottle Solutions

Scaling up from our development services to full scale commercial drug productmanufacture or transferring existing commercial products, Almac Pharma Servicescan meet your commercial drug product manufacturing requirements.Our range of commercial scale dry blending, and wet and dry granulation technologysupports the commercial drug product manufacture of granules and oral powders forreconstitution. -

Brochure Packaging Solutions for Auto-Injectables

With increasing demand for packaging solutions for auto-injectables, and acompressed timeline to supply these products to patients, Almac Pharma Services’commercial facilities in the UK, EU & US, provide flexible, quality led commercialpharmaceutical packaging solutions tailored to meet your specific needs, from initialartwork and pack design to commercial drug product packaging, serialisation anddistribution.Our high and low throughput commercial pharmaceutical packaging operations provide flexibility and efficiency inthe processing of all types of presentations. We’re able to support both high volume marketed products and niche/orphan drug launches and ongoing lifecycle supply. -

Brochure Paediatric Packaging Solutions

With over 50 years’ experience in providing packaging solutions, we understand theunique requirements for paediatric medication packaging. Almac’s comprehensiverange of paediatric packaging options ensures safety, convenience, and adherence toregulatory standards for children’s medications.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.jpg)

-file109222.jpg)