AUTOCOATER

Product Description

Brilliant Process Machinery Pvt. Ltd.

-

IN

-

2015On CPHI since

-

2Certificates

-

25 - 49Employees

Company types

Primary activities

Categories

Specifications

Brilliant Process Machinery Pvt. Ltd.

-

IN

-

2015On CPHI since

-

2Certificates

-

25 - 49Employees

Company types

Primary activities

More Products from Brilliant Process Machinery Pvt. Ltd. (17)

-

Product PLANETORY MIXER

Planetary Mixer is ideal for mixing of wet/dry materials. It has a homogenous mixing action.

The planetary motion of the beater enables faster and better mixing of material at a considerably lesser time.

It is high shear mixer and is available in variable speed ... -

Product COATING PAN

Coating Pan are made of stainless steel all contact parts of S.S 304, S.S 316, S.S 316L

The unit is Equipped With suitable hot air Blower with thermostatic Control. No foundation requirement.

Models available from 12” –24”-36”-48” - 60”

Adaptability for lower size of coating pan &a... -

Product WFI STORAGE VESSEL

Vertical / Horizontal Distilled Water Storage Tank is available in both jacketed and non jacketed design. If WFI is to be stored overnight or for a longer period of time, then it is essential to keep it in hot condition, at around 80 C. Distilled Water Storage Tank with jacketed design, where heating mediu... -

Product MANUFACTURING TANK

•Unique structure with the advance technique imported for abroad, be made of SUS304/316L; inner surface polished, outer surface frosted; meets the GMP standard. Be widely used in the field of producing foods, beverage, and medicine for cooling, heating, and mixing.•Be made of SUS304/316L, polished insid... -

Product STARCH PASTE KETTLE

cGMP construction with AISI 316Q contact parts.Hemispherical bowl with either steam, electrical or oil heating options.Options available for with / without agitator.Tilting provided for ease in unloading of final products.Higher capacity models available without tilting but with bottom outlet.Capacities av... -

Product SVP / LVP MIXING VESSEL

CAPCITY: 20 LTRS TO 10000 LTRS. Complete vessel designs as per ASME Code. Instrumentation & connections comply with BPE & EHEDG guideline. Zero dead leg Aseptic design Flush Bottom Outlet diaphragm valve. Vessel design & fittings are designed for CIP / SIP able. Volume monitoring by load c... -

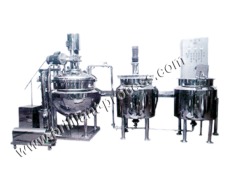

Product Oinment Cream Mfg. Plant

•The ointment units are ideal tools for the pharmaceutical and cosmetic industries for the production of ointment, creams, tooth paste, lotions and other emulsions and homoginizations.

Particular attention has been paid to ease cleaning, efficiency of agitators, ease of maintenance.

... -

Product SYRUP MANUFACTURING PLANT / AUTOMATIC LIQUID ORAL

•Model Available - 100 Ltrs. to 3000 Ltrs. Batch Capacity. •(GMP MODEL)

THE FACILITY CONSISTS OF :

Sugar Syrup Vessel

Online sugar syrup pre-filter

Manufacturing Vessel

Storage Vessel

... -

Product FLUID BED DRYER

The use of ‘Fluid-Bed’ technique on industrial scale, has been considerably on the increase, specially for drying, cooling, calcination, agglomeration, combustion and in many other unit operations, due to its manifold advan... -

Product Rapid Mixer Granulator (R.M.G.)

•RAPID MIXER GRANULATOR : BRILLIANT mixer is designed to meet special needs of tablet manufacturing technology. This is achieved by reducing processing time, more homogenous mixing, uniformity of Granule size and above all maintaining improved hygienic standards within the highest GMP norms

... -

Product AIR TRAY DRYER

AIR CIRCULATION:

A highly effective recirculating air system is provided. The filtered air, heated electrically, is recirculated with fresh air in selected proportions for optimum drying. Uniform air circulation, controlled temperature, sturdy construction and large working space are ... -

Product ZERO HOLD UP FILTER PRESS

Reverse Flow Zero Hold Up Type: Here the direction of flow of liquid is exactly opposite to the flow in standard filter i.e. the impure liquid to be filtered enters the filter from the bottom into the center channel & goes to the top of each plate. The clear filtrate flows out from openings o...

Brilliant Process Machinery Pvt. Ltd. resources (1)

-

News Invitation

We are an ISO 9001:2015 & CE Certified company, pioneers in designing & manufacturing of all kinds of Processing machinery for Pharmaceuticals, API, Cosmetics, and Chemicals Industries especially in Liquid, Ointment, Tablet, Powder, and Injectable section machinery such as Ointment Cream Mfg. Plant, Syrup Mfg. Plant, Reactor, Filter Press, SVP Mixing Vessel, Autoclave, WFI Storage Tank with Loop Systems, FBD, RMG, Blender, Autocoater, Tray Dryer, VTD, Sifter, PLM, Multi-Mill etc. from lab scale to large volume production scale. All our equipments are conforming to cGMP, WHO, USFDA guidelines. We also provide all documentation such as DQ/IQ/OQ/PQ/ FAT/SAT along with our all equipments.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance