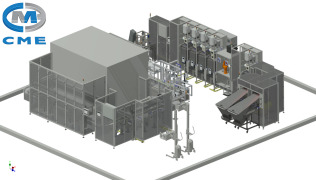

Bottle Sealing and Capping

Product Description

CME Ltd

-

GB

-

2022On CPHI since

-

100 - 249Employees

Company types

Primary activities

Categories

Specifications

CME Ltd

-

GB

-

2022On CPHI since

-

100 - 249Employees

Company types

Primary activities

More Products from CME Ltd (2)

-

Product Automated Pharmacy for Clinical Trials (PACE)

A disruptive technology that reduces the time taken to bring new medicines to market.

The system fills pill bottles with different types of drugs, in tablet or capsule form, without the risk of cross contamination, whilst maintaining complete traceability throughout the system. This turnke... -

Product Bottle Fill Systems

CME’s filling station is designed to accept bottles from a wide range of input sources and different sizes of bottle. On arrival each bottle can be scanned to read the contents of a 2D Matrix Code or Bar Code to verify correct variant before being transferred into the filling station.

CME Ltd resources (1)

-

Technical Data Bottle Fill Systems

CME’s filling station is designed to accept bottles from a wide range of input sources and different sizes of bottle. On arrival each bottle can be scanned to read the contents of a 2D Matrix Code or Bar Code to verify correct variant before being transferred into the filling station

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance