Edetate Disodium USP (VERSENE™ NA)

Product Description

Dow

-

US

-

2018On CPHI since

-

3Certificates

-

5000+Employees

Company types

Primary activities

Categories

Specifications

Dow

-

US

-

2018On CPHI since

-

3Certificates

-

5000+Employees

Company types

Primary activities

More Products from Dow (8)

-

Product Excellence in Every Molecule: API and Excipients

https://www.dow.com/en-us/market/mkt-healthcare-hygiene/sub-health-pharmaceuticals.html -

Product Excipients for Gel Capsules

Enhance your oral formulations with high quality ingredients. Contact us to learn about the excipients in development.

-

Product Excipients for Oral Health products

CARBOWAX SENTRY Polyethylene Glycols (PEGs) are widely used oral care products because of their mildness and solubility in water. They are effective in a wide range of toothpaste formulations, including those for anti-cavity, whitening and sensitivity. And they are used in oral gels to deliver target... -

Product Excipients for Topical Formulations

Learn how you can maximize your topical drug formulations using CARBOWAX SENTRY Polyethylene Glycols (PEGs). Contact us to learn about our excipients in the pipeline.

-

Product PEG as API for Laxatives

CARBOWAX SENTRY Polyethylene Glycols (PEGs) 3350 and 4000 Uninhibited are active pharmaceutical ingredients (APIs) produced to address the needs of the most stringent requirements of the pharmaceutical industry. These APIs are well-known in the treatment of chronic constipation. Functioning as an osmotic... -

Product CARBOWAX™ SENTRY™ Polyethylene Glycol (PEG)

CARBOWAX™ SENTRY™ PEGs common applications include: carrier/plasticizer in gel capsules, base for face/neck lotions, providing formulation stability in toothpaste, binder for tablets, shampoo wetting agent, and more. CARBOWAX™ SENTRY™ PEGs are available in average molecular weights ranging from 3... -

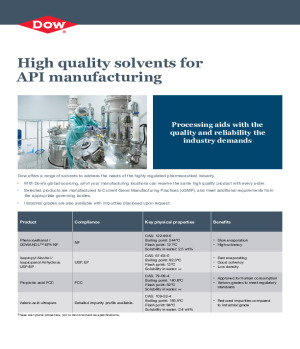

Product High Purity Solvents for API Manufacturing

Detailed impurity profiles are available for industrial grade solvents. In addition, multiple high purity solvents are available:

- Phenoxyethanol /DOWANOL™ EPh NF: CAS: 122-99-6

- Isopropyl Alcohol /Isopropanol AnhydrousUSP/EP: CAS: 67-63-0

- Propionic acid... -

Product Processing aids – surfactants: TRITON X-100 & TERGITOL 15-S-9

Large Molecule (Biologic) API Production:

Dow’s TRITON™ and TERGITOL™ surfactants are used to inactivate virus envelopes, lyse cells, and buffer RNA extraction solutions. As the only producer of TRITON™ X-100 (CAS No: 9036-19-5), which has been trusted by the industry for deca...

Dow resources (25)

-

News Dow achieves eighth ISCC PLUS certification for Polyurethanes plants in Europe

Italy-based polyurethanes plant at Correggio is latest in a series of independent verifications for circular and bio-circular solutions. -

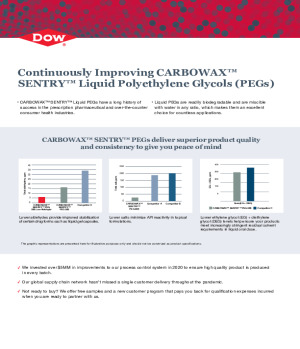

Brochure CARBOWAX™ and CARBOWAX™ SENTRY™ Polyethylene Glycols (PEGs)

CARBOWAX™ and CARBOWAX™ SENTRY™ Polyethylene Glycols (PEGs) are highly versatile excipients and active pharmaceutical ingredients (APIs) produced to meet the exacting requirements of the pharmaceutical industry -

Brochure Enhance your oral formulations with high quality ingredients

CARBOWAX™ SENTRY™ LPEG and MPEGs are pharmaceutical excipients which can be used in the manufacturing of capsules as hydrophilic fillers for solubilization of the API, but also as plasticizer in the coating of the gelatin capsules. -

Brochure Enjoyable, effective, and easy to use ingredients

Enhance topical formulations with CARBOWAX™ SENTRY™ Polyethylene Glycols (PEGs) -

Brochure Processing aids with quality and reliability the industry demands

Whether you’re in the business of small or large molecule API manufacture, we are here to support you. Dow delivers a wide range of solvents and a variety of surfactants - of TRITON™ X-100 and TERGITOL™ - used to inactivate virus envelopes, lyse cells, and buffer RNA extraction solutions -

Brochure High quality solvents for API manufacturing

Dow offers a range of solvents to address the needs of the highly regulated pharmaceutical industry. With Dow’s global sourcing, all of your manufacturing locations can receive the same high quality product with every order. Please visit our API manufacturing page and click on the brochure to selected products that are manufactured to Current Good Manufacturing Practices (cGMP), and meet additional requirements from the appropriate governing bodies. Industrial grades are also available with impurities disclosed upon request. -

Brochure High-temperature heat transfer fluids

Dow fluid specialists can help you design, operate, and maintain your heat transfer system for optimum performance and economy. The family of DOWTHERM™ and SYLTHERM™ heat transfer fluids available from Dow are high performance products. The line includes two distinct fluid chemistries – synthetic organic and silicone. You’ll find an overview description of our full line of synthetic fluids, plus recommended applications on this brochure, including pharmaceutical industry. -

Brochure 2023 INtersections Progress Report

Through our Decarbonize & Grow and Transform the Waste strategies, we progressed our sustainability targets. Discover how -

Brochure Dow´s approach to Safer Materials

To develop safer materials that meet the needs of our customers and the value chain, we monitor regulatory trends and use cutting-edge science. -

Brochure Dow announces targets to conserve water and nature

Dow expands Protect the Climate targets to include climate adaptation benchmarks focused on water and nature. -

Whitepaper CARBOWAX™️ SENTRY™️ PEG formulation guide for cosmetics, pharmaceuticals, and more

CARBOWAX™️ SENTRY™️ Polyethylene Glycols (PEGs) are widely used in the consumer health and pharmaceutical industries because of their unique formulation properties, low toxicity, mildness and water-solubility. CARBOWAX™️ SENTRY™️ Methoxypolyethylene Glycols (MPEGs) are primarily used as intermediates in the synthesis of pharmaceutical actives, for example, in esterification reactions. They have also been found to enhance the water solubility of less polar compounds and are used in topical applications. -

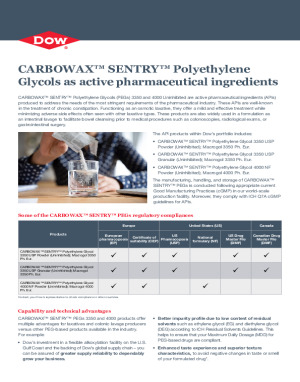

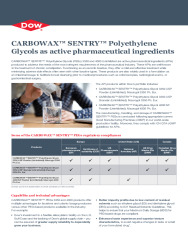

Whitepaper CARBOWAX™️ SENTRY™️ Polyethylene Glycols as active pharmaceutical ingredients

CARBOWAX™️ SENTRY™️ Polyethylene Glycols (PEGs) 3350 and 4000 Uninhibited are active pharmaceutical ingredients (APIs) produced to address the needs of the most stringent requirements of the pharmaceutical industry. These APIs are well-known in the treatment of chronic constipation. Functioning as an osmotic laxative, they offer a mild and effective treatment while minimizing adverse side effects often seen with other laxative types. These products are also widely used in a formulation as an intestinal lavage to facilitate bowel cleansing prior to medical procedures such as colonoscopies, radiological exams, or gastrointestinal surgery. -

Whitepaper Dow excipients for consumer health and pharmaceuticals

CARBOWAX™️ SENTRY™️ Polyethylene Glycols (PEGs), CARBOWAX™️ SENTRY™️ Methoxypolyethylene Glycols (MPEGs), and VERSENE™️ NA Edetate Disodium are among the most versatile excipients produced to meet the requirements of the consumer health and pharmaceutical industry. Our products have been successfully used in over-the-counter and pharmaceutical formulations to impart enhanced solvency, lubricity, hygroscopicity, stability and other important functional properties. -

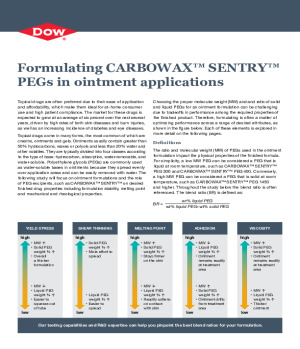

Whitepaper Formulating CARBOWAX™️ SENTRY™️ PEGs in ointment applications

There is an increasing preference for skin delivery remedies that can be self-applied at home. Formulators must strive to deliver active ingredients through an exceptional sensory experience to patients of all ages. CARBOWAX™️ SENTRY™️ Polyethylene Glycols (PEGs) have a long history of use in topical applications because they meet all compendial requirements. Connect with our technical team for more information via our CPHI online portal. -

Video Reimagining How You Work with Your Excipient Supplier: Product Quality Beyond Compendial Requirements

This session was originally broadcast as part of the CPHI Worldwide 2021 digital content programme. One of the top priorities of pharmaceutical companies in bringing new products to market is to prove a drug substance is safe and effective against a certain illness. As you would expect, especially in the beginning stages of development, companies primarily focus on the API itself and not necessarily the excipients that will go into the final drug product. Instead, compendial requirements and guidelines such as those from ICH exist to ensure excipient quality and safety. Not only this is important from a regulatory perspective, but excipient quality can also impact product performance, even if those excipients meet all compendial requirements. In this session, you will learn about: Recent regulatory developments relating to residual impurities in pharmaceutical excipients Challenges in analytical methods to meet increasingly stringent targets How you can work with your excipient supplier to ensure high product quality

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance