Kiefel GmbH

About Kiefel GmbH

Certifications

Categories

-

DE

-

2015On CPHI since

-

3Certificates

-

250 - 499Employees

Company types

Meet us at

CPHI Milan 2024

Fiera Milano, Italy

08 Oct 2024 - 10 Oct 2024

Products from Kiefel GmbH (5)

-

Product Filling machines

Kiefel filling and sealing units are equipped with high quality mass flow-meters and can also be operated as stand-alone devices, whether as fully automated unit, or Table Top Filling module. They stand out due to their compact design, high reliability and efficiency, and high-precision filling technol... -

Product SOLUTIONPERFORMER Form Fill Seal machine

Would you like to produce top-quality infusion, multi-chamber or CAPD bags at the best price-performance ratio? Get to know our new flexible SOLUTIONPERFORMER. The standardized and automatic KFS Form Fill Seal machine is highly competitive while being the perfect solution for both sim... -

Product Bioprocess bag machines - Flexible solutions for producing highest-quality bioprocess bags & containers

Our fully- and semi-automated bag manufacturing equipment allows flexible and fast production of highest-quality single-use bioprocess bags, ranging from 20 ml 2D bags to multi-thousand-liter 3D container designs, including mixer, bioreactor and fermenter bags.Whether you opt for non-PVC (PE, PP) or E... -

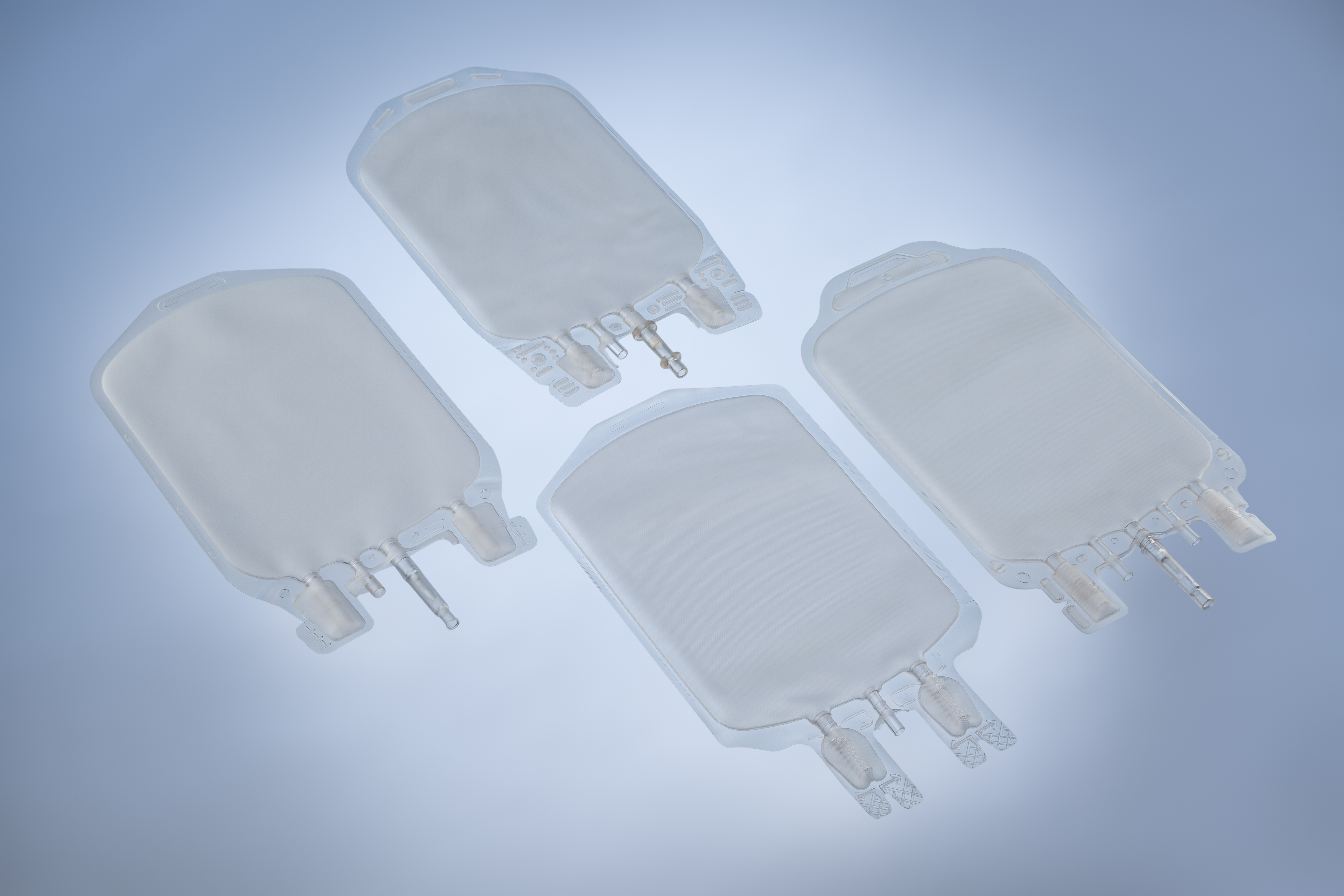

Product Blood bag machines

Kiefel is the market leader in the construction of machines used to manufacture blood bags. Special attention is paid to fulfilling and monitoring the highest quality criteria when manufacturing blood bags. Our innovative solutions let us offer our customers just the right level of automation to m... -

Product Urine catheter products & drainage bag machines

We offer a wide range of solutions for the manufacturing of various urine catheter products; from processing the pre-fabricated catheter, welding the urine receiving bag, to manufacturing and integrating in-bag fluid dispensers into the receptacle, or applying lubricant along the catheter.

...

Kiefel GmbH Resources (1)

-

Video Kiefel Medical Products & Services at a glance

Discover our brand new Medical video and dive right into the #KiefelMedical world. Get exciting insights into our daily business within the #Medical and #Pharmaceutical sector. With a Kiefel Medical machine you are able to produce competitive #medicalproducts like IV bags, blood bags and filters. With our reliable systems a lot of high-level companies already trust in us.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance