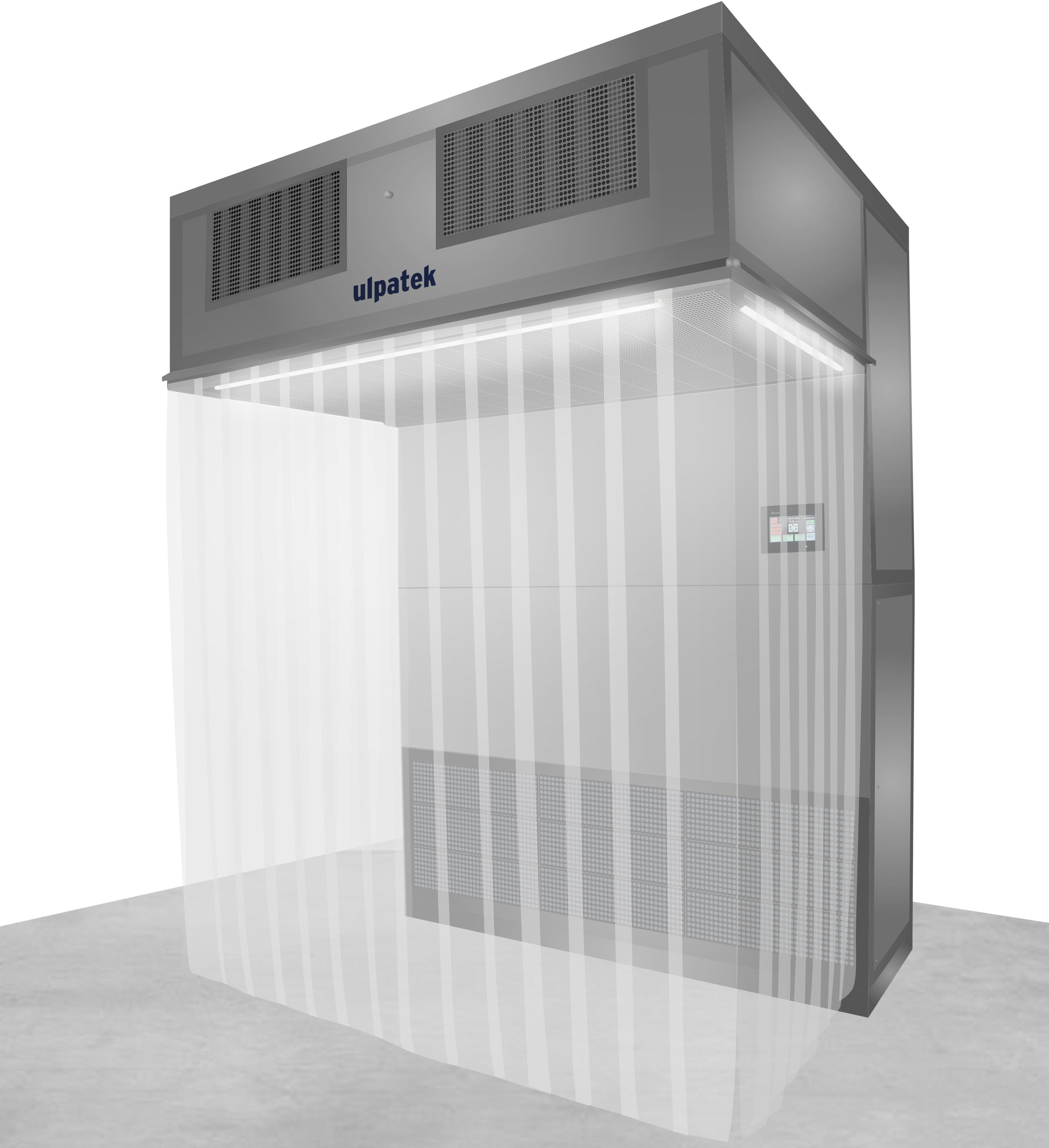

Laminar FLow Cabins for Weighing And Sampling

Product Description

ULPATEK FILTRE TIC.SAN.A.S

-

TR

-

2015On CPHI since

-

2Certificates

-

100 - 249Employees

Company types

Categories

Specifications

ULPATEK FILTRE TIC.SAN.A.S

-

TR

-

2015On CPHI since

-

2Certificates

-

100 - 249Employees

Company types

More Products from ULPATEK FILTRE TIC.SAN.A.S (2)

-

Product Laminar Flow Units with FFUs

Laminar Flow Cabin with FFUs is made of special aluminum profiles and stainless steel frames. Cabins are either designed to be hanged from ceiling or comes with rolling wheels. Transparent hygenic curtains, variable speed controller, differential pressure gauges, test aerosol nozzles are some of the standa... -

Product Safe Change Filter Housing

USCH can provide a filter change free of contamination. Each housing is equipped with a fully sealed bag (BIBO) system to protect of people, process and environment. Wide range of particule and chemical filters can be used in the in the unit .Special design is available depending on filtration stage and ai...

ULPATEK FILTRE TIC.SAN.A.S resources (2)

-

News Ulpatek meet industry expectations in combatting the pandemic

Ferhat GÜRER, Ulpatek Air Filter’s Export Sales Manager, shared the operations of Ulpatek Air Filter in 2020 and their goals for 2021. -

Brochure Ulpatek General Catalogue

The founders of ULPATEK company has been active in the field of cleanroom air conditioning in pharmaceutical, health and food sectors for more than 40 years. They know the importance of clean air and filtration from experience. Having the cleanroom filtration requirements in their mind, they established the new company to produce wide range of filters to answer the demands of air conditioning systems from simple AHU’s to cleanrooms.ULPATEK is manufacturing at their modern production facility in a closed area of 12.650 m² in Istanbul. Coarse, Medium, Fine, EPA, HEPA and ULPA filters are produced in cleanroom environment according to European standard ISO 16890 and EN 1822 by most advanced machines in the field of filtration. ULPATEK has ISO 9001 certificate from TUV NORD of Germany to ensure quality operations since the day production started and the most important certificate according to ISO 16890 called “Eurovent” has been received on the March of 2014.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance