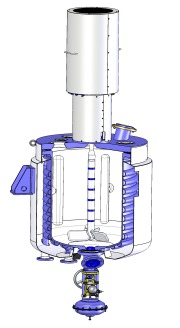

Pharma Reaction System

Product Description

De Dietrich Process Systems GmbH

-

DE

-

2016On CPHI since

Company types

Categories

Specifications

De Dietrich Process Systems GmbH

-

DE

-

2016On CPHI since

Company types

More Products from De Dietrich Process Systems GmbH (2)

-

Product Complete API-Synthesis Plants

Whether you are installing a new kilo lab, pilot plant, or large-scale API manufacturing facility, or if you need to upgrade your existing facility to meet new requirements or regulation, De Dietrich Process Systems can provide a customized solution incorporating containment, CIP, SIP, automation and mixing. -

Product Glass-lined Pharma Reactor

Advanced solutions for efficient cleaning Characteristics • A wide range from 63 l up to 630 l • Optimization of the thermal transfer and the mixing performances (OptiMix®) • Glass-lined flat cover with excellent surface finish and pad nozzles • Polished 316L Stainless Steel sheathing on dri...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance