Synthesis Theta

The recipe for efficiency by Universal Pack

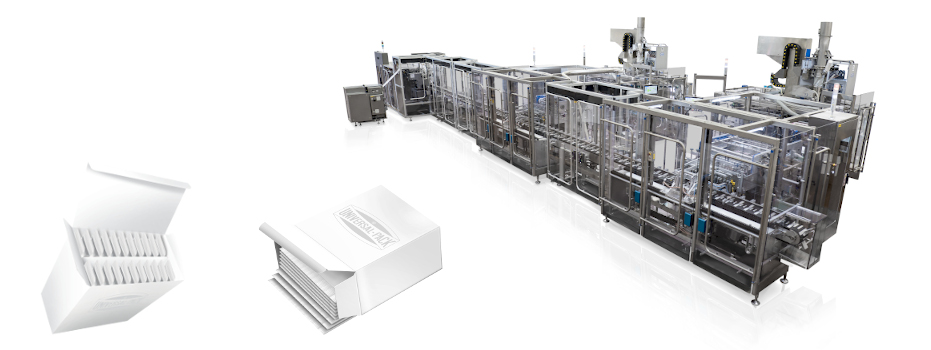

The remote installation of a complete packaging line for 4-side-seal sachets has just ended. The pharmaceutical multinational company chose Universal Pack mainly for the high output in terms of cartons/minute, the possibility of compacting the sachets stack with ad hoc systems, the maximum flexibility in formats and reduced blueprint as opposed to competitors’ offer.

The Project

The collaboration between the multinational company and Universal Pack starts with a project concerning the making of a complete packaging line for producing 4-side-seal sachets and automatically inserting them in pre-glued cartons.

The need of the buyer was to adopt a technological solution that would allow maximum production flexibility, high output and compliance with pharmaceutical market requirements, in one solution.

Universal Pack’s answer has satisfied all the specific requests and is structured in the following areas:

The machine speed for 4-side-seal Theta: this vertical machine model allows to reach horizontal machines output, while reducing footprint to a large extent and keeping greater flexibility.

Another key factor in the choice is the compact footprint of the whole line proposed by Universal Pack compared to the equivalent offer by other market players.

The quality in terms of sachets endurance, product integrity and aesthetic beauty produced by Theta machine also affected the decision. The high quality is made possible by a new horizontal sealing concept and a specific liquid cooling system for the sealing parts, avoiding film and product stress during dosing.

Total flexibility in sachet and carton size: this is a key factor especially for contracting companies and companies managing several production batches.

Another reason not to underestimate is the possibility to compact the stacks of sachets before transferring them to the cartoning machine: this process allows to gain greater stability and insert more sachets with equal carton size.

In addition, complying with the goal of operations simplification, adjustments and formats change take place without the need for extra tools.

In order to guarantee the highest precision at any output, the packaging line was equipped with multilane checkweigher, thousandth load cells with direct feedback to the single lanes of the dosing unit. There is also a station for the manual reintegration of rejected sachets.

The extractable dosing system can be placed at ergonomic height to facilitate cleaning operations and format change.

To reduce operational costs while keeping maximum efficiency, it was agreed to provide a completely customized assistance and maintenance plan, including training, on site and remote assistance, predictive maintenance, 4.0.

Remote equipment installation.

10 Advantages of the Project:

• Output speed

• Compact blueprint

• Sachet quality

• Total flexibility in size

• Tool-free adjustments and format change

• Carton volume minimization

• Multilane checkweigher

• Extractable dosing unit

• Operational costs minimization

• Remote plant installation

Related News

-

News First offers for pharma from Medicare drug price negotiations

Ten high-cost drugs from various pharma manufacturers are in pricing negotiations in a first-ever for the US Medicare program. President Biden’s administration stated they have responded to the first round of offers. -

News The 2024 Pharma Outsourcing Forecast: strategic partnerships across global landscapes

For the pharmaceutical industry, outsourcing drug development, manufacturing, and research operations to contract organisations is not just a passing trend – increasingly, the partnership between drug sponsor and drug vendor is one of vital impor... -

News Gerresheimer predicts weight-loss drug deals to account for 4% of yearly growth

Dietmar Siemssen, CEO of German primary packaging manufacturer Gerresheimer, states that approximately 4% of the company’s revenue growth each year to come from deals with drugmakers of weight loss and diabetes products, particularly GLP-1 class ... -

News Novel approach to creating sustainable packaging from rice husks

Researchers have created a new approach to the designing of eco-friendly nanofibres extracted from rice husks, addressing the critical need for sustainable packaging materials in food and biopharmaceutical products. -

News Eli Lilly’s Zepbound makes leaps and bounds in weight-loss drug market

In the last week, Eli Lilly has announced their partnership with Amazon.com’s pharmacy unit to deliver prescriptions of Zepbound. Zepbound has also surpassed Novo Nordisk’s Wegovy for the number of prescriptions for the week of March 8.&nbs... -

News Coronary drug-coated medical device receives US FDA approval

Boston Scientific announced the FDA approval of their medical device AGENT Drug-Coated Balloon (DCB) for the indication of coronary in-stent restenosis in coronary artery disease patients. -

News CPHI Online Webinar Series – Innovative Strategies for B2B Pharma Marketeers

On February 20, 2024, CPHI Online hosted a webinar on Innovative Strategies for B2B Pharma Marketeers. Featuring expert speakers from across the pharmaceutical value chain, this webinar delves into how B2B pharma marketeers can create better content to... -

News Generics threat to Merck’s Bridion as Hikma seeks pre-patent expiry approval

Merck has disclosed they received notice from Hikma Pharmaceuticals for seeking a pre-patent expiry US FDA approval for Hikma’s generic version of Merck’s Bridion.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)