24

Oct

2023

MEGGLE Excipients

Exhibitor at CPHI Barcelona 2023 stand 5D20, Excipients

About Us

Categories

-

DE

-

2015On CPHI since

-

1000 - 4999Employees

Company types

Event information

CPHI Barcelona 2023

-

24-26 October 2023

-

Fira Barcelona Gran Via, Spain

-

Visit us at stand 5D20, Excipients

Products Featured at CPHI Barcelona 2023

-

Product FlowLac®

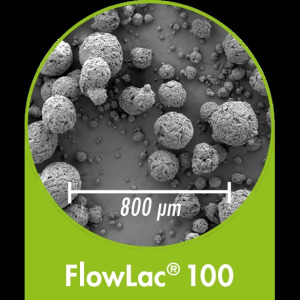

FlowLac® The product FlowLac® is produced by spray-drying a suspension of fine milled alpha-lactose monohydrate crystals in a solution of lactose. When lactose in solution is spray-dried, a rapid removal of water is taking place, whereby amorphous, non-crystalline lactose is formed in addition to crystalli... -

Product InhaLac®

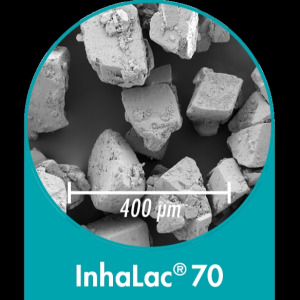

InhaLac® stands for a lactose, which is, in particular, suitable for use in pulmonary and nasal drug delivery. Inhalation aerosols offer the potential for needle-free systemic delivery of small molecule drugs as well as therapeutic peptides and proteins. An industry standard in dry powder inhalation formul... -

Product Tablettose®

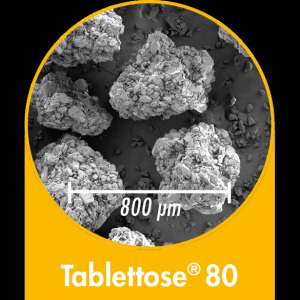

Tablettose® The product Tablettose® is manufactured by a continous spray agglomeration process, where water is used as the binder and is sprayed onto fluidized fine milled lactose particles, creating liquid bridges to form agglomerated lactose.

Tablettose®, especially designed for Direct-Compression,... -

Product Lactose Product Portfolio

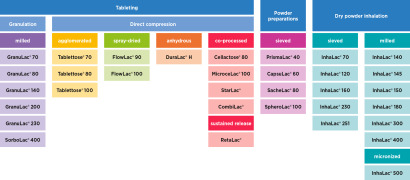

MEGGLE has it: The Right Lactose Product for all Needs

The world of lactose is our whole world. With this in mind, our products are aligned specifically to your needs and applications. For further information on any product shown here, please see the detailed, individual product brochure ava... -

Product GranuLac 70 - milled Lactose

GranuLac® types consist of fine lactose particles. Due to its good compressibility and blending properties lactose is the most frequently used filler for wet granulation. Milled lactose has a limited flowability and therefore has to be granulated before the production of tablets.

MEGGLE GmbH & Co. KG Resources (2)

-

Brochure MEGGLE Product Decision Flyer

Product Overview and Decision Matrix -

Video MEGGLE Spray-dried Lactose

MEGGLE has it.The right spray-dried lactose product for direct compression

Spray-drying (SD) opened the door for lactose in Direct Compression (DC) and had a major impact on tableting technology. After initial quality problems, SD lactose has become a very frequently used, robust excipient grade in pharmaceutical formulation design.

Nowadays, pharma grade lactose is manufactured first, and then converted into SD lactose, avoiding former browning due to the use of a contaminated mother liquor. SD lactose is an excellent example demonstrating the versatility of this material: Besides thermodynamically most stable polymorph α-lactose monohydrate, a precisely defined percentage of amorphous lactose is created in a tailored particle design process using a lactose suspension.

Important: Amount of amorphous lactose

The amount of amorphous lactose can be determined by the lactose dissolved before the atomization step. Generally, SD lactose grades expose between 10 to 15% amorphous lactose, and an aqueous lactose solution contains a majority of ß-anomer, especially at elevated temperatures. This ratio is basically not changed after dispersion, when due to rapid dehydration no formation of a structured crystal lattice is possible. Lactose molecules arrange more the less randomly containing some traces of water. Lack of an ordered structure is seen the reason for its adhesive, more plastically deforming compaction behavior, while sphenoidal, structure-giving, α-lactose monohydrate crystals (also denoted as “tomahawk”-shaped) tend more to consolidate by fragmentation.

Spray-drying: Modulation of porous particles

A combination of these two compaction behaviors favors synergistically tableting and simultaneously loadability of a compact. In a typical SD process a liquid or slurry is rapidly dispersed into a controlled drop size, and its physical shape is preserved by a hot, counter-flowing gas, streaming against the dispersing atomizer. In SD lactose manufacture only aqueous systems are used, drying agent is just hot air. The formation of spherical aggregates of narrow particle size distribution (PSD) impacts powder technological aspects dramatically: Flowability of product is greatly enhanced by spherical shape of agglomerates and smooth surface enabling excellent tablet mass and content uniformity values. Besides that, SD also allows to modulate porosity of particles, which may be applied increasing compaction performance, as well as reducing lubricant sensitivity.

MEGGLE’s spray-dried lactose grades for direct compression are available under the trade names

FlowLac ® 90 and FlowLac® 100

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance