Aseptic Blow-Fill-Seal packaging machines for the production of ampoules

Product Description

ROMMELAG AG

-

CH

-

2024On CPHI since

Categories

Specifications

ROMMELAG AG

-

CH

-

2024On CPHI since

ROMMELAG AG resources (1)

-

Video BFS overview

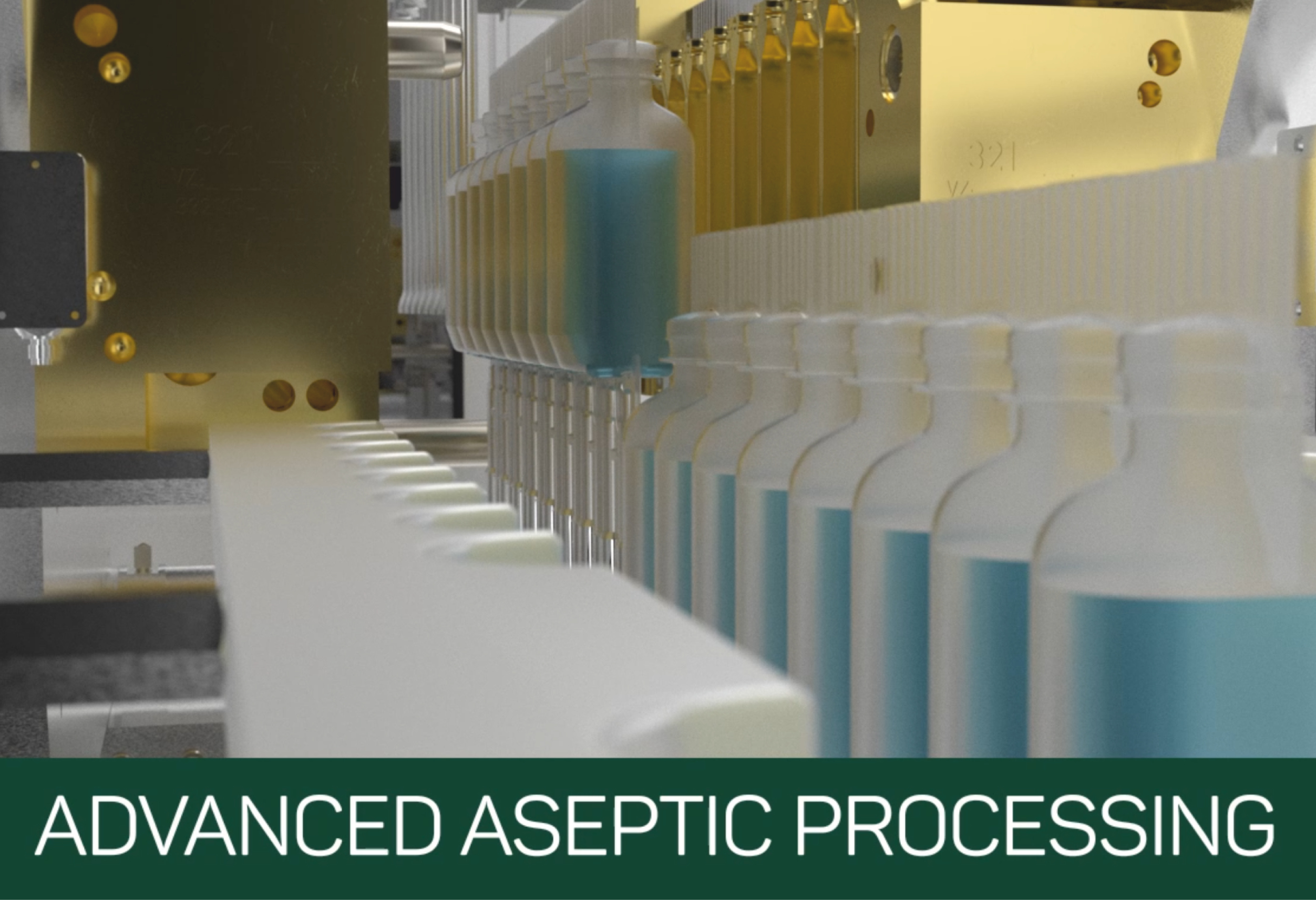

Rommelag is the inventor and global leader of Blow-Fill-Seal technology (BFS) which has been used to package liquid and semi-solid pharmaceutical products since the 1960s. This advanced aseptic process uses plastic polymer material to form, fill and hermetically seal a container in an automated process. With the packaging of sterile liquids (e.g. eye drops, IV solution, injectables, vaccines), gels and ointments Rommelag is present in pharmaceutical, healthcare and also in cosmetic and chemical industries.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance