Intensification Boost for Enzymatic Liquid/Gas Processes by means of Continuous Flow Processing

Intensification Boost for Enzymatic Liquid/Gas Processes by means of Continuous Flow Processing

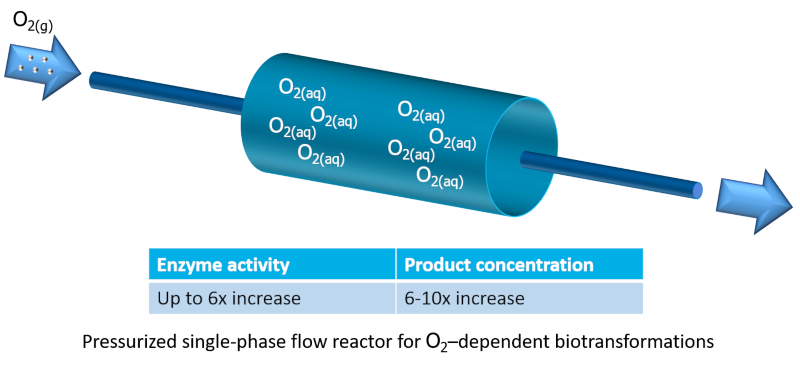

O2-dependent biotransformation reactions have proven difficult in fine chemical manufacturing due to the mass transfer limitations of supplying O2 to the enzymatic reaction, hence affecting the level of efficiency achieved.

Previous research has shown that enzymatic processes involving gases have a high potential for process intensification by implementing continuous flow processing technology.

In a cooperation between acib and Microinnova Engineering GmbH, with more than 15 years of experience in flow chemistry it has been proven that process intensification can be applied using continuous flow processing.

This technology offers a comprehensive solution with a pressurized system that results in a significantly higher level of dissolved oxygen. A continuous flow reactor pressurized to 34 bar enables biotransformation to be conducted in a single liquid phase and significant increase of enzymatic activity was detected already at 10 bar.

For glucose oxidase, the intensification factor for enzyme activity was up to 2.5 and amino acid oxidase showed an intensification factor up to 6 for the enzyme activity. High product concentration has been demonstrated with the concentration being 6 to 10 times higher at 34 bars compared to atmospheric pressure. See also Bolivar J.M., Mannsberger A., Thomsen M.S, Tekautz G., Nidetzky B. (2019) Biotechnology and Bioengineering, 116(3), 503–514.

Find out more in this acib newsletter: https://www.acib.at/wp-content/uploads/76_liquid_gas_P.pdf

Related News

-

Sponsored Content Ashwagandha and Herbal Medicines: Pharma’s Next Big Opportunity

Herbal medicines and nutraceuticals have seen a surge in interest since the onset of the COVID-19 pandemic. Driven by patient interest in prioritising personalised and integrative medicines, the herbal ingredients industry is now faced with concerns pe... -

Sponsored Content Discover Our Organic Mineral Salts as APIs

Discover the range of organic mineral salts that serve as Active Pharmaceutical Ingredients available from Dr. Paul Lohmann®. -

Sponsored Content CPHI Podcast Series: Ursatec – celebrating 30 years of pioneering preservative free

In the latest episode of the CPHI Podcast Series, Digital Editor Lucy Chard spoke with Dominik Rocchi of Ursatec. -

Sponsored Content How healthcare trends inform dosage forms

Capsules encompass one of the most popular solid oral dosage forms for pharmaceutical products, with the global empty capsule market predicted to rise to USD $3.7 billion by 2026. The growth in the capsule market can be partly attributed to the many op... -

Sponsored Content 2023 Pharma Trend Outlook: Innovation, Resilience, and Pharma 4.0

Download our 2023 Pharma Trends Outlook report to discover the trends set to shape the pharmaceutical landscape in the new year, with expert opinions and insight from across the pharmaceutical value chain. -

Sponsored Content CPHI Podcast Series: Key Considerations in Selecting the Right CMO Partner

In this month's episode we hear from Jayna Blake, Senior Project Manager for Technical Programs at Baxter BioPharma Solutions, on key considerations for successful CMO selection. -

Sponsored Content Size doesn’t matter: How smaller deals are shaping healthcare M&A

Several mega-deals have made a splash in the pharma and life sciences industries over recent years – from AstraZeneca’s acquisition of Alexion for $39 billion to Gilead Sciences’ $21 billion purchase of Immunomedics. With am... -

Sponsored Content Rise in home-based healthcare shaping pharma packaging and drug delivery

The pharma packaging and drug delivery industry has long been synonymous with rapid innovation. As medicine advances and patient needs change, so too should drug packaging and devices. This has been particularly evident during the pandem...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)