Brochure

15 Feb 2022

Microinnova Chemistry Portfolio

PDF 189 kB

Content provided by our supplier

Microinnova Engineering GmbH

-

AT

-

2015On CPHI since

-

5Certificates

-

25 - 49Employees

Company types

Primary activities

Other Content from Microinnova Engineering GmbH (9)

-

Sponsored Content Capacity Boost by Batch-to-Conti Debottlenecking

Space economy is a typical issue for debottlenecking projects. Since a continuous approach reduces mass and heat transfer distances up to a factor of 100, these solutions can easily be integrated into an existing batch environment.

-

Brochure Who is Microinnova?

A short presentation highlighting our expertise! -

Sponsored Content Modular Plants: Speed as the Key Success Factor for Chemical Businesses in the Future

We expect that speed and flexibility will be success factors for chemical businesses in the future.

-

Sponsored Content Corning and Microinnova Celebrate Opening of Advanced-Flow™ Reactor Qualified Lab

Corning Incorporated and Microinnova recently celebrated the opening of the Corning® Advanced-Flow™ Reactors (AFR) Application Qualified Lab (AQL) at their facility near Graz. Application qualified labs enable AFR customers to effectively access continuous-flow demonstrations, experimental trials, feasibility testing, and chemical reaction process development.

-

Video Modular Plants for Smart Manufacturing

My name is Katharina and I will show you how continuous modular plants will change chemical processing for a more sustainable future, using modular plug & play plants. We see some issues with batch processing. Sometimes there are concentration spots, the walls are too hot for the molecules. Our philosophy is that all molecules should have the same processing conditions. This we realize by looking at the critical parameters of the chemistry and selecting the right process intensification technology. Furthermore, the space-time-yield can be maximized by a magnitude or more by reducing mass and heat transfer distances, leading to much shorter residence times and compact designs. Since we already have a continuous operating plant in the lab, scale-up becomes much easier. Continuous manufacturing allows for superior quality control due to advanced PAT. Standardized modules enable a quick realization of reduced time to produce and time-to-market. More infos below video! -

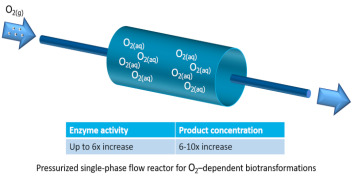

Sponsored Content Intensification Boost for Enzymatic Liquid/Gas Processes by means of Continuous Flow Processing

O2-dependent biotransformation reactions have proven difficult in fine chemical manufacturing due to the mass transfer limitations of supplying O2 to the enzymatic reaction, hence affecting the level of efficiency achieved.

-

Video 8 Differentiators that make Microinnova Unique

Microinnova serves its customers as a one-stop-shop from development to manufacturing plants. The following eight differentiators make Microinnova unique. 1. Microinnova focuses on end-to-end continuous manufacturing, dealing with processes in the area of synthesis, work-up and formulation.

2. We work with a wide range of different process intensification technologies. We select the best technology for each process. We want to enable uniform process conditions for each molecule.

3. We are used to working in regulated environments. We are DIN EN ISO 9001 certified. We can build plants that fulfill typical standards for regulated environments like GMP and ATEX.

4. We can handle various conditions. We can process highly viscous materials like melts, suspensions, precipitates and solids in packed or trickle beds.

Our other 4 differentiators you can find in the video! -

Sponsored Content Microinnova Sponsors Award for Outstanding Process Intensification Work Towards CO2 Reduction

We were honored to have the opportunity to sponsor the 2021 EFCE Excellence Award in Process Intensification.

-

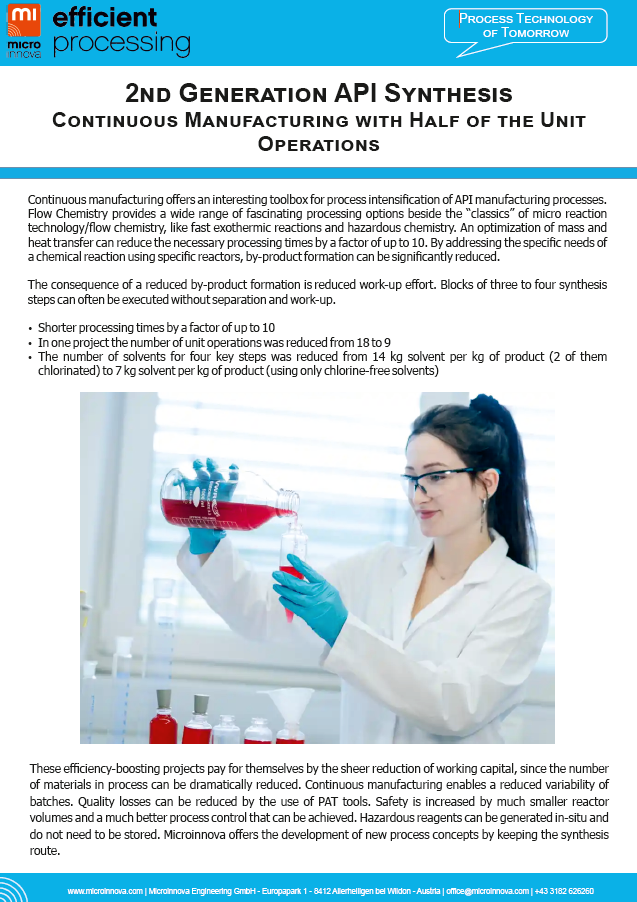

Brochure 2nd Generation API Synthesis

Continuous Manufacturing with Half of the Unit Operations

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance