ROTA Verpackungstechnik

About ROTA Verpackungstechnik

Categories

-

DE

-

2017On CPHI since

-

100 - 249Employees

Company types

Meet us at

CPHI Milan 2024

Fiera Milano, Italy

08 Oct 2024 - 10 Oct 2024

Products from ROTA Verpackungstechnik (8)

-

Product Complete primary packaging processing lines

Rota Verpackungstechnik offers a wide range of products. Contact us for more information -

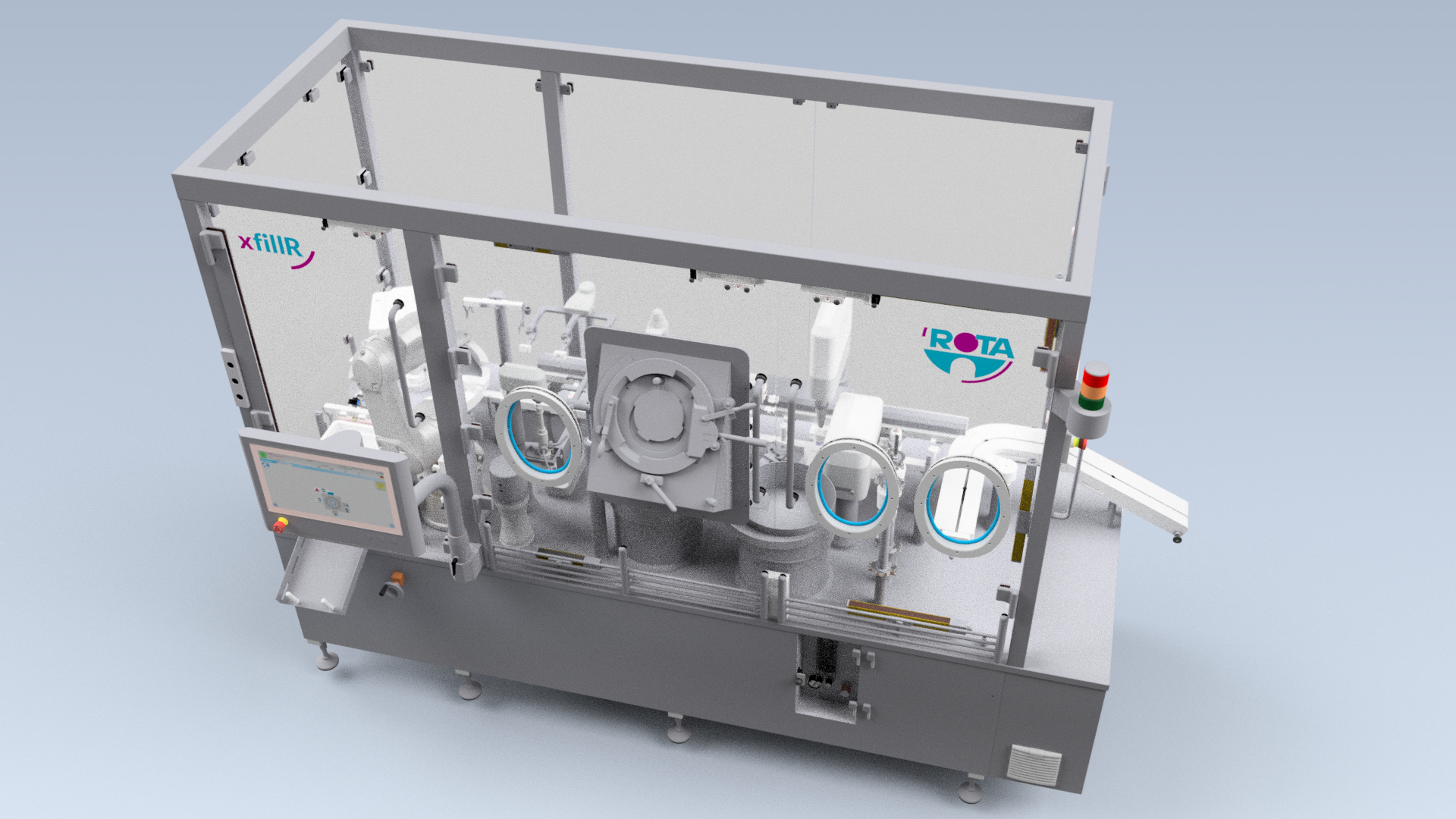

Product Multipurpose small batch filler

xfillR is the first and so far, only multipurpose machine that combines the filling and closing of very different objects such as vials, syringes, ophthalmic bottles, nasal sprays, cartridges in nests, trays and bulk – all in one. -

Product Machines To Wash Containers For Aseptic Processing

Rota Verpackungstechnik offers a wide range of products which includes machines to wash containers for aspetic processing. Contact us for more information -

Product Hot Air Tunnel To Sterilise Depyrogenate Containers

Rota Verpackungstechnik offers a wide range of products which includes hot air tunnel to sterilise depyrogenate containers. Contact us for more information -

Product Machines for Closing Vials With Stoppers

Rota Verpackungstechnik offers a wide range of products which includes machines to close vials with stoppers. Contact us for more information -

Product Machines For Filling Ampoules And Glass Or Plastic Vials

Rota Verpackungstechnik offers a wide range of products which includes machines tio fill ampoules and glass or plastic vials. Contact us for more information -

Product Machines for nested containers processing

Automatic or semi-automatic bag removal Filling and Closing machines Denesting machines Labelling and Assembling machines -

Product Machines To Labels Ampoules, Vials, And Syringes

Rota Verpackungstechnik offers a wide range of products which includes machines to labels ampoules, vials, and syringes. Contact us for more information

ROTA Verpackungstechnik Resources (1)

-

News xfillR: New universal small batch filler

xfillR is the first and so far, only multipurpose machine that combines the filling and closing of very different objects such as vials, syringes, ophthalmic bottles, nasal sprays, cartridges in nests, trays and bulk – all in one.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance