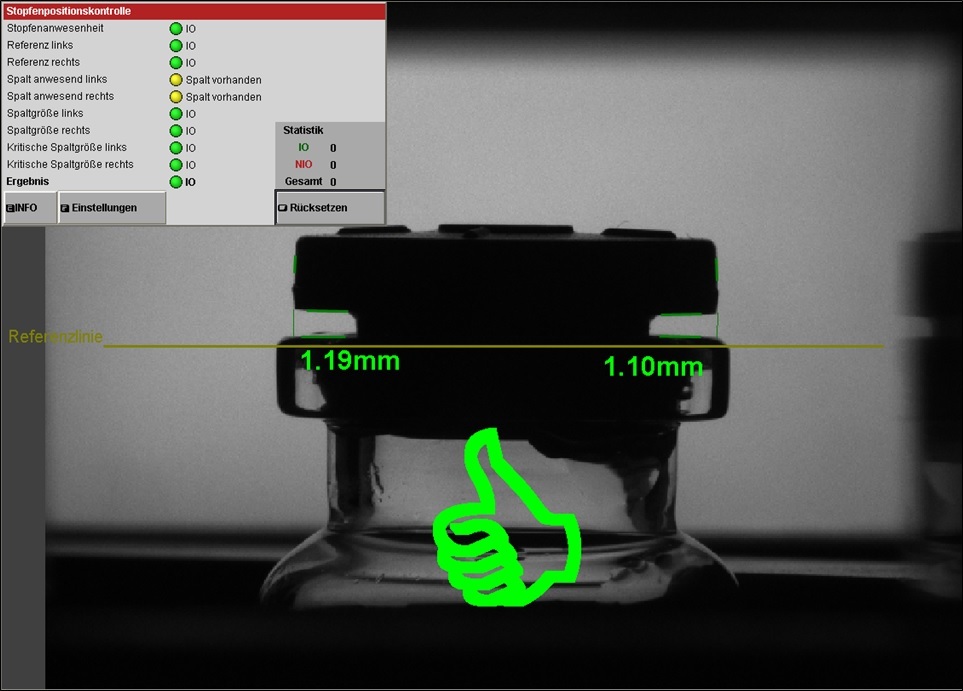

In accordance with

GMP, Appendix 1, when filling vials with pharmaceutical products, the stopper gap

must be checked using a suitable inspection system before the crimped cap is

fitted in order to minimize microbiological contamination.

Machine Vision is the best technology to perform these inspections and measure the

gap width between the bottom edge of the stopper and the top of the vial. Normally a gap of 1 mm is allowed, measured at

conveying speeds of 40 m/min.

The Octum image processing system for stopper gap inspection meets all customer

requirements. The stopper gap is measured at four locations with an accuracy of

±0.05 mm or better. The cameras are housed in an insulator-capable stainless

steel housing together with the LED lighting. This space-saving layout permits

the system to be ideally integrated into the filling line for both use cases

with vials in the linear conveying direction as well as to circular path

movement in the transport star.