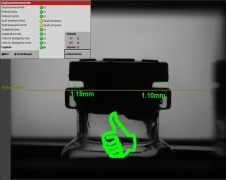

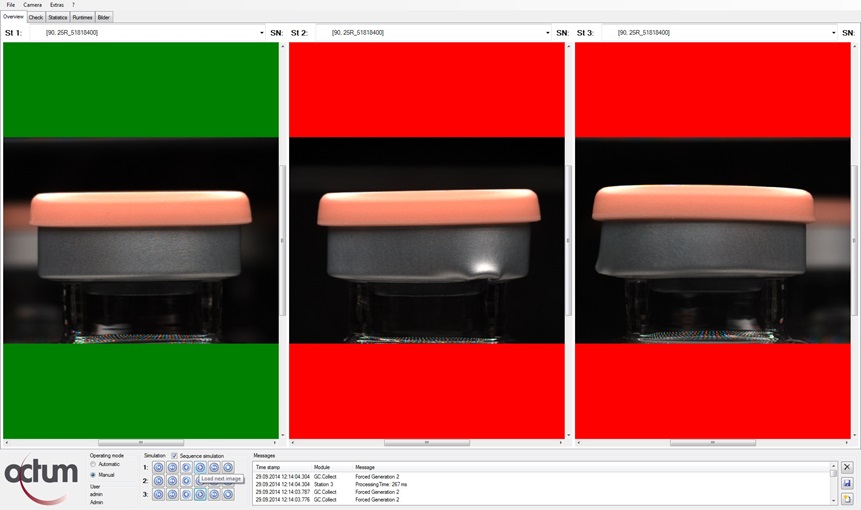

Vial Crimping Inpsection in Filling & Capping Machines

Product Description

OCTUM GmbH

-

DE

-

2019On CPHI since

Categories

OCTUM GmbH

-

DE

-

2019On CPHI since

More Products from OCTUM GmbH (2)

-

Product Inspection System for Pippettes, Cups and Droppers

Pipettes, Cups and droppers are devices for dosing liquids in medical technology. For the conditional use of these mass products accuracy, cleanliness and safety are mandatory requirements. As well there must be no risk of injury to the user. To ensure that the dosed quantities of liquid are corr... -

Product Stopper Gap Inspection System

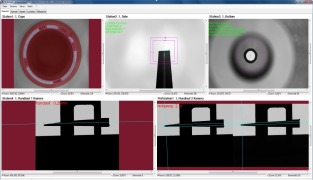

In accordance with GMP, Appendix 1, when filling vials with pharmaceutical products, the stopper gap must be checked using a suitable inspection system before the crimped cap is fitted in order to minimize microbiological contamination. Machine Vision is the best technology to perform these inspectio...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance