WAB IMPA°CT REACTOR

Product Description

WAB US

-

CH

-

2023On CPHI since

-

1Certificates

-

100 - 249Employees

Company types

Categories

Specifications

WAB US

-

CH

-

2023On CPHI since

-

1Certificates

-

100 - 249Employees

Company types

More Products from WAB US (3)

-

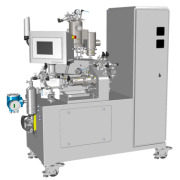

Product DYNO®-MILL

GRINDING & DISPERSION TECHNOLOGY

Wet grinding technology focuses on the controlled real size reduction, dispersion and deagglomeration of solid particles in a liquid medium. Particle finenesses in the micro to nanometer range can be achieved. For more than 60 years, WAB-GROUP&n... -

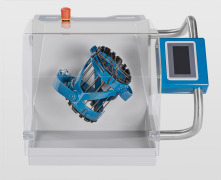

Product TURBULA®

With the TURBULA series you can produce compounds with the highest quality requirements and excellent reproducibility.

The high mixing efficiency of these 3D shaker mixers results in the shortest mixing times and thus an extremely gentle mixing process. The mixers are easy to operate an... -

Product dyna-MIX®

For a homogeneous mixture, the dyna-MIX mixes solids, solids with liquids and liquids. It is used when high-quality mixing results are required for higher quantities.

Its robust design also allows the processing of larger material quantities with high specific weights. A high-quality contro...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance