Delivering on mRNA-based therapeutics: innovations in applications and packaging

.png)

Since the onset of the COVID-19 pandemic, the innovative potential of mRNA vaccines and therapeutics has raised questions regarding their manufacturing, packaging, and storage/transportation. Learn about how the pharmaceutical supply chain is meeting the demands of cutting-edge drugs and therapeutics.

The COVID-19 pandemic, though disruptive in many socio-economic ways, allowed the pharmaceutical industry to demonstrate the innovative potential of mRNA therapeutics on a global scale. With many mRNA-based drug and therapeutic candidates currently in development, questions and considerations have been raised concerning storage, packaging, and transportation. In particular, the need for manufacturers and packaging experts to provide cold chain storage to maintain the stability of drug products is a pressing issue for those interested in the mRNA therapeutic space [i]. Ensuring the stability of the mRNA-based products remains a challenge for developers and manufacturers – protection against certain types of degradation (e.g. enzymatic) may introduce degradation risks elsewhere, and choosing the appropriate containment vessels for these formulations is an issue in and of itself [ii].

Here we look at several mRNA-therapeutic pipelines for different indications, including vaccines for cancers, infectious diseases, immunotherapies, and monoclonal antibody therapeutics, and the considerations needed for manufacturing and packaging mRNA-based products.

mRNA therapeutics for existing and emerging diseases

Research into therapies utilising mRNA gained increased attention when the COVID-19 pandemic prompted pharma giants such as Pfizer, AstraZeneca, and Moderna to invest in one of the most expeditious rollouts of a therapeutic in recent history [iii]. Certain advantages associated with mRNA-based therapeutics include the mediation of more efficient transfection and protein expression that lasts longer over traditional protein-based biologics and drugs [iii]. However, mRNA therapeutics are not a novel idea – the first investigation into an mRNA-based therapeutic started in 1992 but was met with complications related to stability and immunogenicity.

In theory, an mRNA therapeutic’s mechanism of action will be to produce a protein or peptide through protein synthesis during transfection of the cell, whether in vitro or in vivo. With theoretically higher transfection efficiency and lower toxicity than DNA-based drug products, as the product does not need to enter the cellular nucleus, mRNA therapeutics provide the opportunity to investigate treatments for previously ‘uncurable’ diseases [iii]. As a negatively charged molecule sensitive to various RNA enzymes (RNases), it is difficult for mRNA to enter the also negatively charged cell membrane to translate the functional proteins necessary for a potential therapeutic to function [iii]. mRNA-based drug development has stalled until recently, with priorities shifting towards DNA-based biotechnological platforms and the rise of cell and gene therapies [iv]. Advances for mRNA research have thus focused on immune modulation, stabilisation, purification, and delivery, which allowed for the rapid development and rollout of the COVID-19 vaccines seen in recent years [iv].

With such advances in mRNA research for therapeutics, interest in broader use in drug products has picked up pace in the last decade. Some notable mRNA-based therapeutics include:

mRNA-based monoclonal antibodies

Targeted drug therapies such as mAbs can recognise specific proteins on cells, making them especially useful in cancer therapies [v]. The design of mAbs, however, is notoriously difficult – research into plasmid DNA-encoded mAbs have only recently come to wider attention in the industry [vi]. mRNA-mAbs offer improved antibody therapy efficacy, particularly for the treatment of tumours and cancerous cells, and can help rapidly design specific mAbs safely [vi]. Targeted cells are transformed into ‘factories’ that can translate nucleic acids into functional mAbs, allowing for the patient’s cells to synthesize the required antibodies [iii].

Vaccines for infectious and/or autoimmune diseases

While mAbs are a type of immunotherapy, other mRNA-based immunotherapies have also gained traction in recent years, mainly for the treatment of previously untreatable infectious diseases, allergies, and autoimmune diseases. The most prominent example of an mRNA vaccine against an infectious disease are the current COVID-19 vaccines developed by Pfizer/BioNTech and Moderna [iii]. These vaccines rely on mRNA technology to synthesize the viral spike glycoprotein on a SARS-CoV-2 virus in vivo, as well as cause entry of the virion into target cells to induce immune responses. While variants of the SARS-CoV-2 virus have emerged since the onset of the pandemic, chimeras of the spike glycoprotein have also been developed to manufacture mRNA vaccines to encompass these variants.

Similar vaccines can utilise this antigen therapeutic approach – delivering a viral encoding mRNA to target cells – to vaccinate against infectious viral diseases such as influenza, HIV, respiratory syncytial virus, herpes simplex, and rabies [iii].

Cancer vaccines

Cancer immunotherapies, under which vaccines fall, aim to activate and/or stimulate anti-tumour immunity within the host [vii]. When injected, the vaccine delivers mRNA that encodes tumour-specific/associated antigens for cellular uptake by antigen-presenting cells. When the cells present these tumour-associated antigens, the immune response is activated and induces an mRNA-based anti-tumour response [viii]. mRNA vaccines for the treatment of cancer present several potential advantages over other immunotherapeutic options: they are generally tolerated well by patients, present no genome integration that risks insertional mutagenesis, and are non-infectious as no pathogenic agents are utilised, offering a safe, specific, and relatively cost-effective treatment option for cancer patients [vii, viii].

Silvia Gallina, Product Management for Syringe Platform at Stevanato Group, credits the many advantages of mRNA-based therapeutics for their rise in treating cancers: “RNA-based therapies are widening the scope of cancer treatments, for example. Oncology was historically the primary indication for RNA-based therapies and so, not surprisingly, it is leading the way when it comes to the current RNA pipeline. BioNTech and Moderna both plan to deliver personalised cancer vaccines by using sequencing to identify crucial mutations in a patient's cancer cells, and subsequently manufacturing an mRNA shot to elicit an immune response against that individual's cancer1.

Moreover, off-the-shelf combinations of common cancer mutations found in many patients are being developed, providing precision without losing scalability. Cancer vaccines could also work in combination with established checkpoint inhibitor therapies2. Although conceptually similar to CAR T-cell therapies, the RNA approach offers significant advantages. Profiling of patient samples is getting faster and cheaper as sequencing costs are steadily declining, small-batch manufacturing is possible and RNA also works at scale3.”

However, clinical trials for cancer vaccines have been plagued by various challenges concerning highly variable tumour antigens and a comparably low immune response generated by the vaccine. There have been few trials reporting on the efficacy and immunogenicity of mRNA vaccines across several different cancer types, with no approved therapeutic mRNA-based cancer vaccine on the market – the US FDA have only approved two prophylactic vaccines targeting viruses known to account for cervical cancers (HPV) and liver cancers (hepatitis B virus) as of publication [vii, viii].

What’s in store for mRNA therapeutics: packaging and more

With mRNA vaccines and therapeutics entering the mainstream consciousness since the first approval of mRNA vaccines against COVID-19, public demand for and increased interest in mRNA therapeutics have fuelled the market to a valuation of USD $39.9 billion in 2021 and a CAGR of 1.7% from 2022 to 2030 [ix]. Yet, interest in mRNA therapeutic innovation is still to be matched with interest in their packaging – an integral component of any therapeutic development and commercialisation process.

Special delivery: ‘packaging’ at the cellular level

To understand the requirements for primary, secondary, and even tertiary packaging of mRNA-based therapeutics, it is important to understand how the drug product is delivered into and remains stable within the body until its effects are required. As Jay Natarajan, PhD Director, Strategic and Technical Marketing APAC and Andreas Kappel, Innovation Strategist, at Evonik Health Care, state: “There are several key factors that need to be considered when designing an effective mRNA-payload, delivery vehicle or manufacturing process for safe and effective cancer vaccines for multiple indications. These factors include the choice of adjuvants, antigens, and delivery vehicles, as well as the administration routes, dose, and frequency of administration. The three main classes of delivery vehicles that are in clinical trials for administration of mRNA-based cancer vaccines include lipid nanoparticles (LNPs), lipoplexes and dendritic cell cancer vaccines.” Many enzymes found throughout the body rapidly degrade mRNA before it reaches the cell [x].

To prevent this, the appropriate particle packaging is required. The development of the SARS-CoV-2 vaccine introduced the LNP as a delivery method, which are currently in use by the Moderna vaccine and Pfizer/BioNTech vaccine [xi]. LNPs, when administered intravenously or intramuscularly, can sufficiently deliver and transport the mRNA vaccine to its intended target site. However, subcutaneous administration of LNPs may cause significant inflammation – such administration would be utilised in self-administrative medical devices, which would benefit those with chronic diseases that require regular doses [x].

The mRNA-based vaccine’s specific indication may affect manufacturing and packaging decisions: “While there are few examples of vaccines that encode a single antigen such as KRAS (Kirsten Rat Sarcoma), most vaccines encode either a fixed or even a patient-specific mixture of characteristic antigens for cancer immunotherapies. This is challenging from a manufacturing perspective due to variable batch size requirements (a few litres) compared to a commercial manufacturing scale for COVID-19 vaccines (hundreds of litres), adding a potential layer GMP regulatory hurdles for personalized mRNA cancer vaccines.

In addition, most mRNA-based cancer vaccines are being investigated as combination therapies with immunomodulators such as pembrolizumab (anti-PD1) or CAR-T cell therapy, or with anticancer agents, which could impact several aspects of the supply chain,” Natarajan and Kappel comment. Gallina adds that “some encapsulating nanoparticles or vectors used for delivery are highly sensitive, and might require low-temperature storage, dedicated manufacturing operations, as well as multiple technological platforms, and the need for optimised formulations to prevent chemical degradation.” Other methods of delivery aim to overcome these limitations posed by LNPs. These include such methods as self-assembled polymeric micelles, nanohydrogels, and gold nanoparticles [xi]. Each of these modes present different challenges when considering requirements for packaging, storage, and transportation for mRNA therapeutics.

To increase the complexity of working with mRNA-based therapeutics, the physical form of the drug product can also impact packaging decisions. Christy Eatmon, Global Subject Matter Expert, sterile drug products, pharma services at Thermo Fisher Scientific, states that “from a primary packaging perspective, mRNA therapeutics are typically aseptically filled into the same containers as other sterile injectable products. However, many mRNA injectables are stored frozen for long-term stability. Freezing a suspension in a vial can be challenging when it comes to vial integrity during freezing and potential stopper hardening, which can lead to leaks and potential sterility issues. To ensure that freezing of stoppers does not have an impact on container closure integrity (CCI, studies have been performed by multiple stopper suppliers to assess container closure at frozen conditions.”

New challenges and new opportunities for all

While Gallina states that “the complex properties of mRNA [pose] a challenge for both the performance of primary packaging and the effectiveness of fill and finish operations,” there exists room for opportunities in packaging innovation. “mRNA solutions, as well as some encapsulating nanoparticles or vectors used for delivery, are highly sensitive and might require low-temperature storage. They require dedicated manufacturing operations, as well as multiple technological platforms, and they need optimised formulations to prevent chemical degradation,” Gallina comments. Manufacturers can also benefit from the challenge: “For manufacturers, managing these typically high-value and small-batch drug products means implementing a flexible production strategy that provides control over the many variables that have the potential to compromise the process. This means addressing the risk of container breakage, which can lead to product wastage and lost productivity, and the risk of particle contamination, which can trigger a costly product recall. In addition, manufacturing must be conducted at an optimum scale, efficiency, and yield,” Gallina explains.

Borosilicate glass vials vs pre-filled syringes

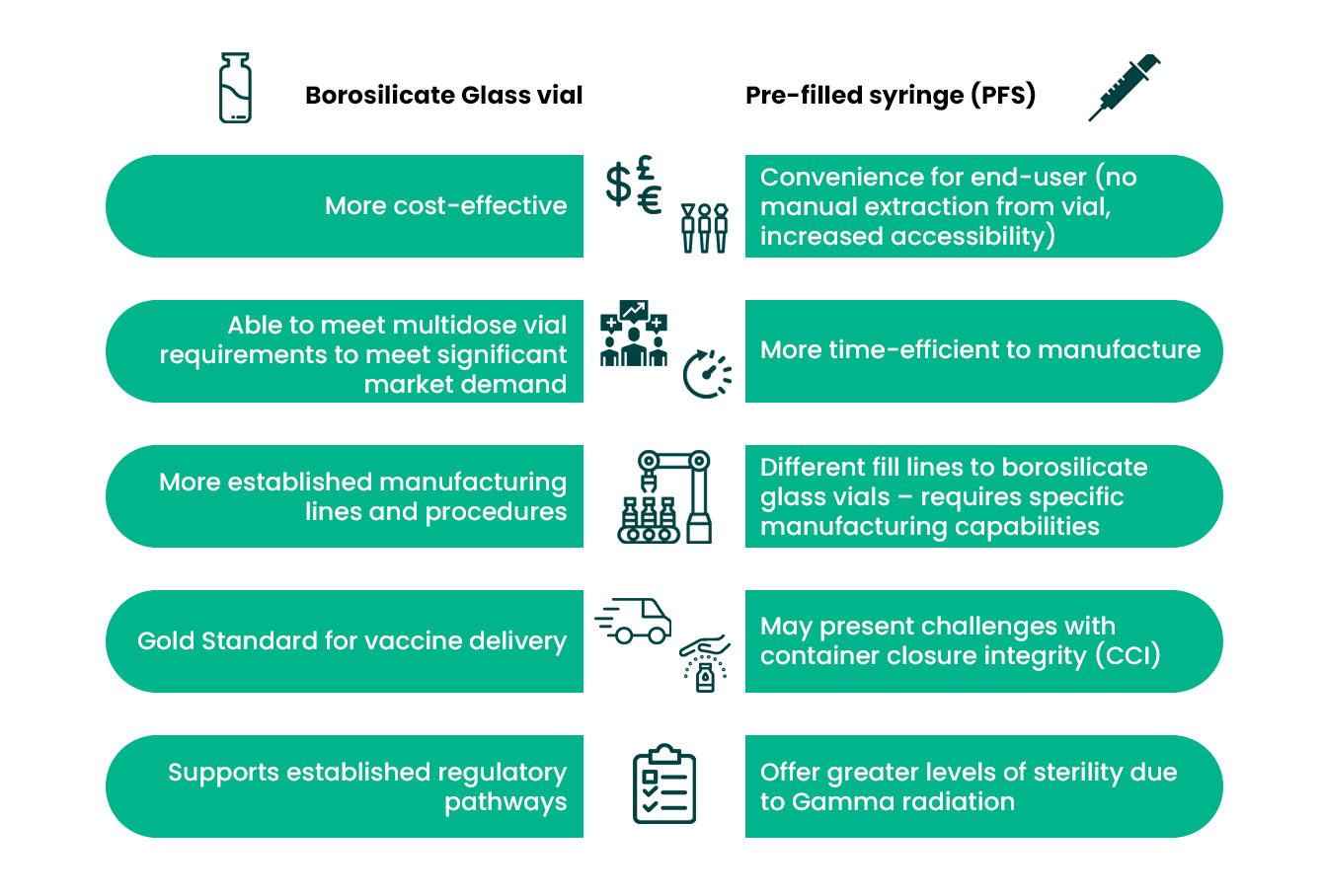

Borosilicate glass vials have historically been the ideal drug containment solution for drug products that provides resistance against chemical reactions and thermal expansion. Many manufacturers with existing fill/finish capabilities are familiar and compatible with borosilicate glass vials and have established regulatory procedures in place for such packaging options [xii].

However, with novel therapeutics often comes new challenges that existing solutions may not account for. Gallina offers the following benefits packaging options such as pre-filled syringes can bring over glass vials:

-

“Lower overfill / dead volume

-

Lower vaccine wastage (doses wasted in multidose vials that were not used in full or in time)

-

Reduced number of steps for injection (and higher speed)

-

Lower risk of injury/ cross-contamination. There are less steps for the injections, so the process is faster and safer, with lower risk of injuries from healthcare professional

-

Dose accuracy independent of preparation so there is less risk of human error”

As the world enters the endemic phase of COVID-19, many experts anticipate a shift towards alternative primary packaging solutions to offer quicker and simpler ways of administering drug products to patients. Eatmon, states that “the most significant benefit of filling into a pre-filled syringe is convenience for the end user by eliminating the need for manual extraction from a vial into a syringe The decision to use vials for mRNA vaccines was likely related to the need to deliver a multidose vial to the market due to the significant demand.”

Pre-filled syringes are not without their limitations, however. Though "the roadmap of vaccine development is likely to lead to increased use of pre-filled syringes,” Gallina comments, “additional challenges [are added] when it comes to meeting CCI requirements in deep-freeze conditions. CCI is one of the biggest challenges to overcome as syringes are far more complex than vials, with several components, and deep cold storage makes it more difficult to maintain the integrity of all the materials. Functionality and mechanical performance also need to be verified to ensure they are not affected by the extreme temperatures.” Eatmon adds that “vials are also more cost-effective than syringes.”

So then, is there a perfect packaging solution for the specific requirements demanded by mRNA-based therapeutics?

The future of packaging for mRNA therapeutic products

Experts expect the rise in novel mRNA-based therapeutics to change how pharmaceutical packaging experts must approach the manufacturing and technological requirements of these drug products. Eaton comments: “As mRNA therapeutics become more common and longer-term stability is available, it may be possible to find a storage solution at refrigerated conditions, rather than frozen. Historically, freezing of pre-filled syringes was not recommended, but as more frozen drug products are developed, data is becoming available for frozen product in syringes.”

Natarajan and Kappel attribute the success of the COVID-19 vaccine campaign witnessed worldwide to innovations in nonviral delivery systems and nucleic-based medicines that impact similar innovations in overcoming their packaging challenges: “Nucleic acids-based medicines and nonviral delivery systems have shown a paradigm shift in how we treat diseases at the genetic, epigenetic, protein, or metabolic level. Specificity, safety, and effectiveness of the delivery systems are key to this evolution, and many innovations can be expected in these areas in the years to come. Stability aspects also play a vital role in the development of these drugs, such as developing freeze-dried products, which can have a strong impact and solve the cold-chain issues with some mRNA–LNP COVID vaccines (related to low-temperature storage and distribution),” they state. “The success story of the COVID-19 mRNA-based vaccines is based on several key innovations that will have a broader impact on the pharmaceutical industry,” they continue. “There have been significant advancements in delivery systems, such as LNP and RNA modifications that have enabled this success. Two critical excipients – ionizable cationic lipids and PEG lipids – have led to the success of COVID-19 mRNA-based vaccines by providing storage stability, stability upon administration with high potency, and ensuring safe use in humans.” Natarajan and Kappel also anticipate the continued collaboration and collective innovation amongst contract organisations across the pharmaceutical supply chain in delivering the manufacturing, distribution, and packaging requirements demanded by mRNA-based therapeutics, from CROs, CDMOs, and CPOs alike.

In general, Gallina foresees continued use of glass vials with syringes making their way into phase II clinical trials: “Glass vials are the preferred option for primary packaging when speed to market is the key driver in drug product development,” Gallina explains. “When looking at lifecycle management (LCM), syringes are already an approved option in phase II clinical trials. This means mRNA therapeutics can be launched directly in syringes with all the [benefits].” Gallina also gives a trend outlook on packaging innovations and makes a case for packaging companies to continue to address current and future needs from pharma companies developing mRNA therapeutics: “Cold storage is critical to the success of mRNA therapeutics, so the main challenge for pharma companies is to ensure their products perform correctly in tests at the lowest temperatures. The latest packaging trends include not only glass but also polymer syringes. When it comes to the route of administration, the trend is still driven by intramuscular syringes rather than subcutaneous. Therefore, the sanitary operators are still the key deliverers of the doses.”

For now, it seems that the continued use of glass vials may be the most viable option for packaging mRNA therapeutics, though there may be a slow but sure shift towards adopting pre-filled syringes [ii]. While research into providing innate mRNA drug stability include such intriguing approaches as aqueous solutions, freeze-drying, and ‘mRNA-printing at the point of use, these methods are still in the early stages of development and subsequently are subject to regulatory concerns [ii]. Exploring existing and new packaging options for stabilizing and transporting mRNA drug products can thus be a sensible approach for pharma companies to consider.

Summary

The field of mRNA-based therapeutics, while having garnered significant traction during and after the COVID-19 pandemic, has yet to realise its full potential. The question of how to move these game-changing therapeutics along the pharmaceutical supply chain may rest in what the industry prioritises – time-to-market, drug lifecycle management, patient centricity, or one of the many different considerations all pharma players must account for.

Whatever the outcome, it remains an exciting moment in history for the pharmaceutical industry to showcase the strides made in healthcare innovation, potentially combatting some of the most complex disease profiles impacting patients.

References

1Source: IQVIA Promise Fulfilled? The next decade of cell, gene, and RNA therapies, 2022

2https://biontech.de/science/pipeline

3Cost of NGS | Comparisons and budget guidance (illumina.com)

[i] Chill Out: Understanding the Realities of mRNA Therapeutic Storage [Accessed May 31, 2023] https://themedicinemaker.com/manufacture/chill-out-understanding-the-realities-of-mrna-therapeutic-storage

[ii] Blenke EO, Ornskov E, Schoneich C et al. The Storage and In-Use Stability of mRNA Vaccines and Therapeutics: Not a Cold Case, J. Pharm. Sci., 2(112), 386–403 (2022) https://www.sciencedirect.com/science/article/pii/S0022354922005147?ref=pdf_download&fr=RR-7&rr=7d81ca033fea23b4

[iii] Qin S, Tang X, Chen Y et al. mRNA-based therapeutics: powerful and versatile tools to combat diseases, Signal Transduct. Target Ther. 7(166), 2–35 (2022) https://www.nature.com/articles/s41392-022-01007-w

[iv] Kairuz D, Samudh N, Ely A et al. Advancing mRNA technologies for therapies and vaccines: An African context, Front. Immunol., (13), 1–22 (2022) https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9637871/pdf/fimmu-13-1018961.pdf

[v] Monocloncal antibodies [Accessed June 6, 2023] https://www.cancerresearchuk.org/about-cancer/treatment/targeted-cancer-drugs/types/monoclonal-antibodies

[vi] mRNA Therapeutics [Accessed June 6, 2023] https://acuitastx.com/technology/mrna-therapeutics/

[vii] Miao L, Zhang Y, Huang L. mRNA vaccine for cancer immunotherapy, Mol. Cancer., 20(41), 1–23 (2021)https://molecular-cancer.biomedcentral.com/articles/10.1186/s12943-021-01335-5

[viii] Lund Lorentzen C, Haanen JB, Met O et al. Clinical advances and ongoing trials of mRNA vaccines for cancer treatment, Lancet. Oncol. , (23), 450–458 (2022) https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9512276/pdf/main.pdf

[ix] mRNA Therapeutics Market Size & Share Report, 2022–2030 [Accessed June 8, 2023] https://www.grandviewresearch.com/industry-analysis/mrna-therapeutics-market-report

[x] Improving mRNA Packaging for Better Medicines [Accessed June 8, 2023] https://www.technologynetworks.com/biopharma/news/improving-mrna-packaging-for-better-medicines-348388

[xi] Tian Y, Deng Z, Yang P. mRNA vaccines: A novel weapon to control infectious diseases, Front. Microbiol. , (13), 1–16 (2022) https://www.frontiersin.org/articles/10.3389/fmicb.2022.1008684/full

[xii] How mRNA drugs are changing the game for pharmaceutical primary packaging [Accessed May 29, 2023] https://www.linkedin.com/pulse/how-mrna-drugs-changing-game-pharmaceutical-primary-packaging-/?trk=public_post

Related News

-

News Pharmapack Awards 2024 Patient-Centric Design Award Winner – Dr Ferrer BioPharma

The 2024 Pharmapack Awards celebrated the best in innovation and design for the pharmaceutical packaging and drug delivery industry on January 24, 2024. -

News Pharmapack Awards 2024 - Celebrating Packaging and Drug Delivery Innovation

The 2024 Pharmapack Innovation Awards ceremony celebrated the best in pharmaceutical packaging and drug delivery innovation at all levels. The awards were held on January 24, 2024 at the Paris Expo Porte de Versailles. -

News Women in Pharma: Looking back on 2023 and moving forward to 2024

In this monthly series, we interview women from across the pharmaceutical industry and supply chain to discuss the importance of gender diversity in healthcare, the workplace, and beyond. -

News On track at CPHI Barcelona - The Track Sponsor interview: USP

In our packed out content sessions at CPHI Barcelona this year we focus on some of the hottest topics coming up in the pharma industry, with each track sponsored by a leading expert in the field. -

News Women in Pharma: Marketing for the other half in healthcare

In our new monthly series, we interview women from across the pharmaceutical industry and supply chain to discuss the importance of gender diversity in healthcare, the workplace, and beyond. This instalment highlights not only the importance of ma... -

News Bringing the pharmaceutical supply chain closer to home

The pharmaceutical supply chain has encountered numerous disruptions in the last few years, impacting procurement, manufacturing, packaging, and distribution operations within the pharmaceutical industry. Read about the rise in calls for near/resh... -

News Your Prescription for Marketing Success: Digital Pharma Marketing Toolkit – Free eBook

Download your FREE pharma marketing eBook to learn why it is so important for pharmaceutical marketeers to develop their digital content marketing strategies in order to establish their companies as thought leaders and industry experts. -

News The CPO Starter Pack: Why and When to Bring in a Contract Packaging Partner

Discover the trends affecting the pharmaceutical CPO market, when and why outsourcing may be an enticing option, and what is driving pharmaceutical companies and CDMOs to partner with outsourced packaging and drug delivery organisations. ...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance