Dr. Reddy's Laboratories SA

About Dr. Reddy's Laboratories SA

Certifications

Categories

-

CH

-

2015On CPHI since

-

3Certificates

-

5000+Employees

Company types

Primary activities

Meet us at

CPHI Milan 2024

Fiera Milano, Italy

08 Oct 2024 - 10 Oct 2024

Products from Dr. Reddy's Laboratories SA (13)

-

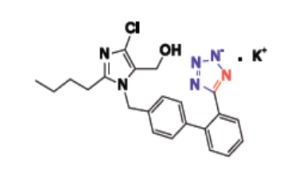

Product Losartan Potassium

Dr. Reddy’s has the capabilities and capacities to manufacture and deliver sartan APIs in accordance with global regulations. Our team of experts developed processes and the analytical methods to avoid the presence of nitrosamine impurities, which are already suitable to confirm future requirements of ... -

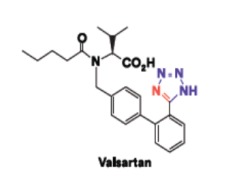

Product Valsartan

Dr. Reddy’s has the capabilities and capacities to manufacture and deliver sartan APIs in accordance with global regulations. Our team of experts developed processes and the analytical methods to avoid the presence of nitrosamine impurities, which are already suitable to confirm future requirements of ... -

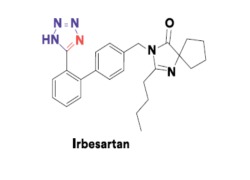

Product Irbesartan

Dr. Reddy’s has the capabilities and capacities to manufacture and deliver Irbesartan APIs in accordance with global regulations. Our team of experts developed processes and the analytical methods to avoid the presence of nitrosamine impurities, which are already suitable to confirm future requirements... -

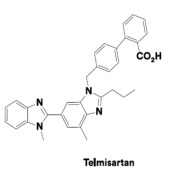

Product Telmisartan

Dr. Reddy’s has the capabilities and capacities to manufacture and deliver Telmisartan in accordance with global regulations. Our team of experts developed processes and the analytical methods to avoid the presence of nitrosamine impurities, which are already suitable to confirm future requirements of ... -

Product Active pharmaceutical ingredients (APIs)

High quality APIs to accelerate your generic product launches. Catering to leading innovator and generic companies across the world, Dr. Reddy’s is recognized as one of the largest API suppliers worldwide. The launch of Dr. Reddy’s XCEED – a digital customer service platform - gives customers inst... -

Product HPAPIs and Oncology Products

Dr. Reddy's Custom Pharma Service offers a complete solution for highly potent and cytotoxic compounds from API development and manufacturing to development and commercial manufacturing of the finished product.

We can support you with an exceptional breadth of capabilities for development a... -

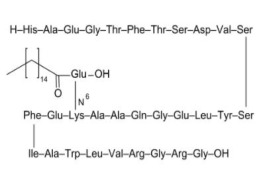

Product Peptides

We help to accelerate the time-to-market of your peptide APIs and formulations

Dr. Reddy’s peptide unit has decades of experience in process development and production of peptide APIs and formulations. This experience is brought to bear on a comprehensive offering that integrates a continuum of ... -

Product Generic APIs

Creating high-quality, affordable active pharmaceutical ingredients (APIs) is one of the keys to help us bring good health to all. Our API Business caters to leading innovator and generic companies across the US, Europe, Latin America, Japan, Korea and other emerging markets. Over the years, we have develo... -

Product Integrated Formulation Develpment and Manufacturing

Dr. Reddy's Custom Pharma Services manufactures outsourced pharmaceutical products in a broad range of dosage forms. Our strategy for success is based on adherence to three principles: outstanding quality; international regulatory compliance; and superior technology transfer capabilities. With ten for... -

Product Activated mPEGs

CPS is one of the leading manufacturers and suppliers of GMP grade Activated mPEGs for the conjugation of proteins, antibody fragments and peptides to improve the stability and pharmo-kinetic properties of biologic drugs. With outstanding GMP capabilities and back integration to high purity mPEG-OH we can ... -

Product Catalysis/Biocatalysis

Dr. Reddy’s Centre of Excellence for chiral technologies is located in the Chirotech Technology Centre in Cambridge, (UK). With over 20 years of experience using proprietary and non-proprietary chiral technologies to produce single enantiomer compounds, this world-class center is equipped with the infrastr... -

Product Differentiated Formulations

Dr. Reddy's Laboratories Ltd. offers a wide range of products which includes Differentiated Formulations. This products division focuses on initiatives to improve patient experience with our products. Better experience results in better compliance, which means better health and outcomes for patients. Conta...

Dr. Reddy's Laboratories SA Resources (8)

-

News Pharma Explained: Active Pharmaceutical Ingredients

What are APIs? As the name suggests, Active Pharmaceutical Ingredients (APIs) are the heart of any dosage form, whether they are oral, injectable or inhaled, and are absolutely essential to the development of a formulated product. -

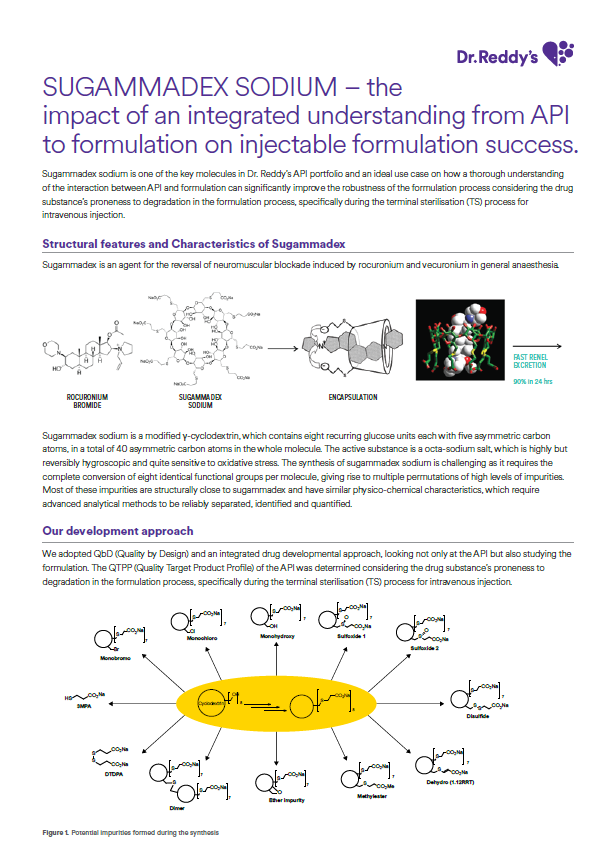

Brochure Sugammadex Sodium API article

Sugammadex sodium is one of the key molecules in Dr. Reddy’s API portfolio and an ideal use case on how a thorough understanding of the interaction between API and formulation can significantly improve the robustness of the formulation process considering the drug substance’s proneness to degradation in the formulation process, specifically during the terminal sterilization (TS) process for intravenous injection. -

News Live Webinar: Strengthening a sustainable API supply chain performance.

At Dr. Reddy’s, we’re in the business of ensuring good health for both people and the planet. Our experts will share insights on our sustainability approach and on how it helps B2B customers support their sustainable supply chain performance while sourcing APIs. Please register here: -

Brochure Dutasteride

• We offer polymorphic crystalline form 2.• A novel synthetic process developed for crystalline form 2.• Quality by design (QBD) based API development for a consistent quality profile -

News Dr. Reddy’s partners with FUJIFILM and Global Response Aid for Avigan® (favipiravir), a potential treatment of COVID-19

Dr. Reddy's Laboratories Ltd. announces partnering with FUJIFILM Corporation through FUJIFILM Toyama Chemical Co. Ltd. and Global Response Aid for the development, manufacture and sales of Avigan® Tablets (generic name: favipiravir), a potential treatment of COVID-19. -

Brochure Pregabalin API

Crystalline form-I i.e., Innovator form.• The control strategy for the API impurity pro le has been designed through quality-by-design (QbD) based development.• Lactam impurity levels are not detected, thus able to achieve USP/ EP compliance after milling - opening a possibility for a wide range of delivery systems -

Webinar Strengthening Diversity, Equity, and Inclusion in Pharma

The pharma industry is aware that it needs to improve the representation of women and minority communities in its businesses. The benefits of diverse teams are clear, yet it isn’t an easy road. How can companies create an environment where people feel safe, thrive, and attract the best?

Approaching Diversity and Inclusion as part of a wider Sustainability / Environment, Social, and Governance (ESG) performance is an essential indicator of pharma companies' commitment to driving I&D for a more diverse and successful workplace, which ultimately also ensures to better serve patients around the world. -

Video Innovation Across Borders: How Pharma and innovators are fighting back against COVID-19 and ways forward

A global pandemic demands a fast response. The research-based pharmaceutical industry is working upstream at extraordinary speed to develop a safe and effective vaccine for COVID19. Pharmaceutical companies around the globe are joining forces and speeding up the process by conducting phases and development in parallel and forging new partnerships and collaboration. The pharmaceutical and life science industry has faced the need to leverage science and technology, developed pre and during the pandemic. Firms are coming up with new ways to maintain production despite disrupted supply chains, or they are mobilizing to design new products as demand for existing products collapses. This discussion will examine how the COVID-19 pandemic is driving pharma and life science companies to collaborate, innovate and prepare for an uncertain future. This webinar was originally aired as part of the CPHI Festival of Pharma.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance