Facility & Process Validation Testing

Product Description

Nelson Laboratories LLC

-

US

-

2018On CPHI since

-

4Certificates

-

500 - 999Employees

Company types

Primary activities

Categories

Specifications

Nelson Laboratories LLC

-

US

-

2018On CPHI since

-

4Certificates

-

500 - 999Employees

Company types

Primary activities

More Products from Nelson Laboratories LLC (4)

-

Product Biocompatibility & Toxicology Testing

Nelson Labs offers a full trifecta of services to meet the requirements of ISO 10993 for Extractables & Leachables, Biocompatibility and Toxicological Assessments of medical devices. Biocompatibility testing is very common in the medical device industry. However, with 24 possible categories, each with... -

Product Extractables & Leachables Testing

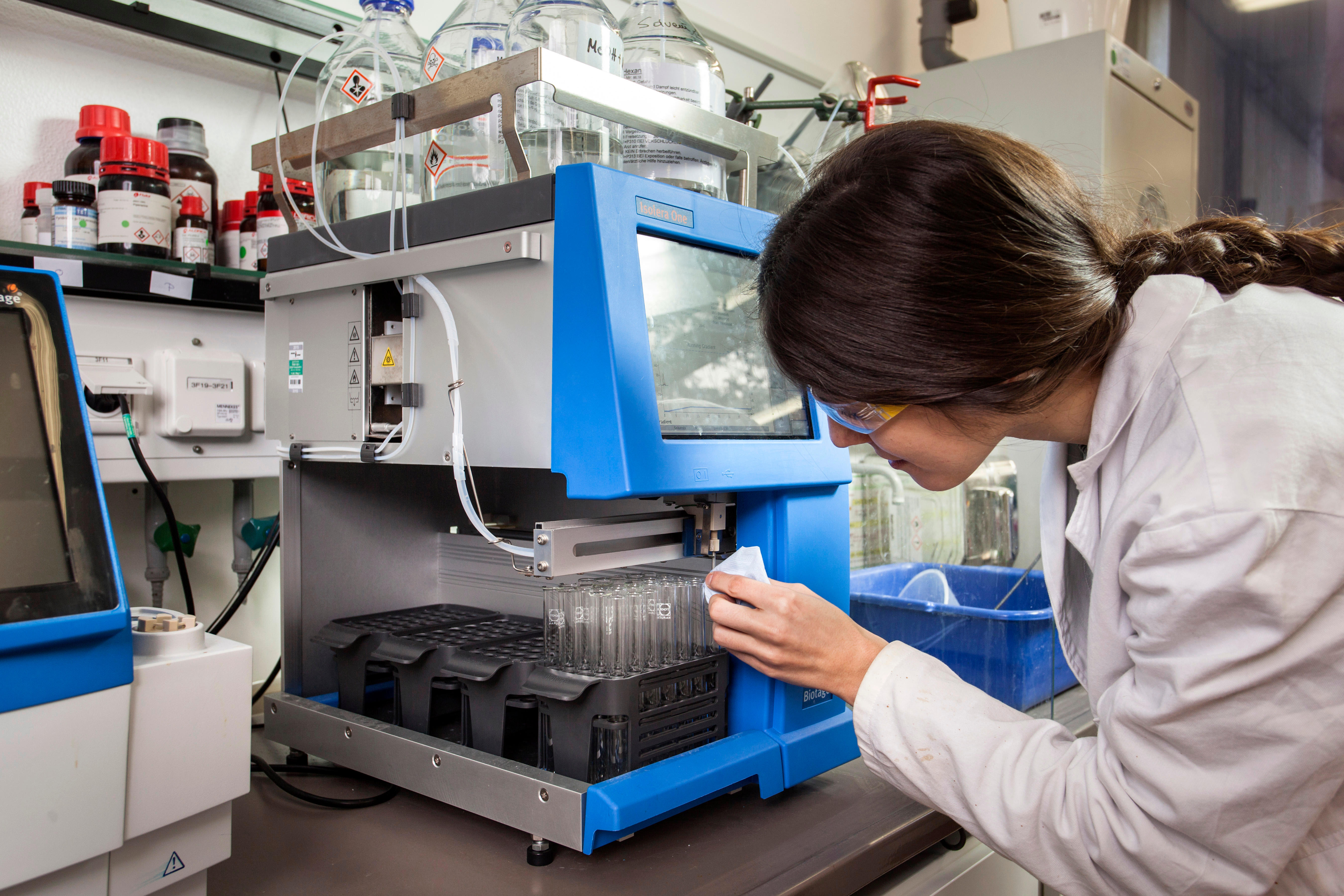

Nelson Labs Europe offers a comprehensive approach toward Extractables & Leachables testing for the pharmaceutical industry. Our approach combines technical and analytical expertise, polymer knowledge and understanding of regulatory requirements, all combined in a tailored approach for our customers. -

Product Packaging Solutions Testing

We offer unparalleled breadth of packaging experience to help our clients deliver safe and effective products to market. Our services encompass consulting, package validation, material qualification and package development. Nelson Labs packaging solutions department has experience with successful valida... -

Product Sterility Assurance Testing

Nelson Labs is a leading provider of sterility assurance test services for medical device, pharmaceutical and tissue manufacturers for both sterile and nonsterile products. Most tests follow United States or European Pharmacopeia (USP or EP) and similar international standards. Medical device standards are...

Nelson Laboratories LLC resources (16)

-

Brochure Extractables & Leachables

Benefit from our Unmatched Experience! -

Brochure Pharmaceutical Test Services

Nelson Laboratories pharmaceutical test services. -

Brochure Identifying Unexpected Impurities In Drug Products

Nelson Labs can help you identify unexpected impurities in drug products. Download our brochure and find out how we can assist you.

Unexpected impurities may create significant stress and anxiety within a pharmaceutical company. These unexpected impurities are not always identified at first, since they often are initially detected with non-specific detectors. At Nelson Labs, specific methods are in place to investigate and identify organic impurities. -

Brochure Services for the pharmaceutical & medical device industries

Download our brochure and find out what services we provide for the pharmaceutical & medical device industry -

Brochure Pharmaceutical Solutions

Read up on the pharmaceutical solutions we provide in our brochure. -

Brochure Why Choose Nelson Laboratories?

Download our brochure and find out how we help safeguarding global health with every test we complete -

Video Nelson Labs Europe

Nelson Labs Europe’s capabilities are complementary and additive to Nelson Labs’ existing testing portfolio and, in combination, makes Nelson Labs one of the premiere global E&L laboratory testing platforms for the pharmaceutical and medical device industries. -

Video The Necessity of Extractable and Leachable Qualifications for Lyophilized Drug Products: Some Fallacies Addressed

The webcast will explain the outgassingmechanism of the lyo-stoppers, which may lead to further accumulation of leachables adsorbed onto the lyo-cake. In addition, an experimental testing strategy will be explained that covers both the discovery, identification, and quantification of those leachables, as well as the formation of secondary leachables through chemical reactions between these reactive leachables and the drug product and its ingredients. -

Webinar A Risk-Based Approach Towards the Assessment of Process-Equipment Related Leachables - Case Study

Manufacturing processes are composed of a complex set of plastic materials that may introduce process-equipment related leachables (PERLs) into the final drug product, thereby potentially compromising its biocompatibility, safety or quality. At the same time, not all manufacturing components have the same likelihood to contribute to PERLs. A risk-based approach in which process conditions, type of process material and composition of the process solution are evaluated, allows the definition of relevant test requirements with respect to extractables and leachables. In this presentation, you'll have the opportunity to explore the main principles of a risk-based evaluation through a case study. -

Webinar Extractables & Leachables Qualification of the Primary packaging for Biological Products

In 2022, the final recommendations of the Product Quality Research Institute were published for Parenteral Drug Products. Apart from the wealth of information and considerations on design of extractable & leachable studies for parenteral drug products in general, it also contains valuable information on specific considerations for biological products. For biological products, not only the safety but also the quality of the product and related concerns about immunogenicity and leachables reactivity come into play. We will give an overview on the recommendations and how it affects the design of an extractable & leachable study for the primary packaging of biologics. -

Webinar On the Origin of Extractable Species

In this webinar, originally broadcast as part of the Pharmapack Europe show, Piet Christiaens, Scientific Director, Nelson Labs talks about the Universe of Extractables and how there are many different types of materials being used in the construct of a Container system. The impurities profile of a material is typically composed of compounds that were intentionally added to a material to protect the material during production or its life cycle or to increase performance or functionality. In this case, he is talking about polymer additives. However, there is even a longer list of compounds that are present in a material that were not intentionally added. These compounds have been introduced during the production process of the material, or they are the result of ageing of the material. The presentation will give an overview – for the most common materials used in the construct of container/closure systems or medical devices – of the main classes of compounds that are often detected in extractable studies. -

Webinar The Necessity of Extractables & Leachables Qualifications for Lyophilized Drug Products

When selecting and qualifying the Primary Packaging for lyophilized drug products, one of the obvious questions is “how deep should one go into the E/L-qualification process of a lyo-container”. As the drug product is in a solid state, it is expected that the interaction between the lyophilized drug product and the components of a lyo-container will be low. This is also reflected in the USP Monograph on Leachables and the EMA Guideline on “Plastic Immediate Packaging Materials” (2005). However, the mechanism of interaction between the lyo-cake and e.g. the rubber stopper (when considering a lyo vial) are not always fully understood. The interaction mechanism is based upon “outgassing” of the rubber stopper, where the lyo cake acts as an adsorbent. Not only can this lead to substantial accumulation of the volatile and semi-volatile leachable compounds onto the lyophilized drug product, it may also induce chemical reactions between the leachables and the drug product, i.e. when the adsorbed leachables show electrophilic properties. When you attend this webinar, you will have: A thorough understanding of the interaction mechanisms between a lyophilized drug product and it's container. An understanding of an Extractables and Leachables study design for a lyophilized drug product -

Video Changing Regulatory Requirements for Extractables & Leachables Testing on Pharmaceutical Packaging Systems

In the past decade, scrutiny has changed in the way EMEA or FDA regulators look at Extractables & Leachables data. Requirements gradually increased without official guidance, which left the Pharmaceutical Industry in the dark. Second-guessing the current position and requirements of regulators to support a submission became the norm. This presentation will address the following: Key success factors of E&L projects. An understanding of what regulators want and how to meet expectations. Facing the reality of the ever-evolving regulatory landscape, analytical testing labs need to be at the forefront with expertise in the field of Extractables and Leachables testing and state-of-the-art technology. Meeting development needs and requirements for the pharma industry and raising the bar for material suppliers. Mitigating risk through successful partnering between drug product vendors, material suppliers and the CRO performing the test. This webinar originally aired as part of Pharmapack Europe 2021 -

Video Where N-Nitrosamine Assessments for Drug Products Meet Extractable / Leachable Qualifications for Pharmaceutical Primary Packaging

Recently there have been a number of drug product recalls due to the unexpected presence of N-Nitrosamines. While in most of those cases, N-Nitrosamine formation occurred at the level of the drug substance synthesis and stability, it is well known and documented that some materials, used in primary packaging can also be a source for NNitrosamine contamination of the packaged drug product (e.g. older grade elastomers and nitrocellulose laminated blister foils). The unanswered question is: do we know everything about the materials of construction of a container closure system and their ability to generate N-Nitrosamines? This presentation will offer insights into how an integrated approach for the N-Nitrosamine risk evaluation for a pharmaceutical container closure system could look like.This webinar originally aired as part of Pharmapack Europe 2021 -

Whitepaper Good Identification Practices for Organic Extractables and Leachables Via Mass Spectrometry

The function of a pharmaceutical drug product or a medical device is to provide the patient with a desired therapeutic benefit. If the drug product or the medical device were pure (meaning without impurities), ideally the therapeutic benefit would be largely realized with minimal adverse patient effects. However, since the practical reality is that drug products and medical devices contain impurities, a patient is exposed to these impurities during treatment and these impurities could potentially trigger an increase of adverse patient effects. -

Whitepaper When Drug Meets Device...

When a medicinal product (drug or biologic) meets a medical device, a combined product is created. Incompatibility between the components can present a danger to the patient, but how can one demonstrate the fit between a medicinal product and a device? This paper describes the relevant definitions, the existing regulatory framework for combined products (or better the lack thereof), and focuses on stability testing to assess drug or biological-device compatibility.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

-file145607.png)

-file122524.png)

-file122528.png)