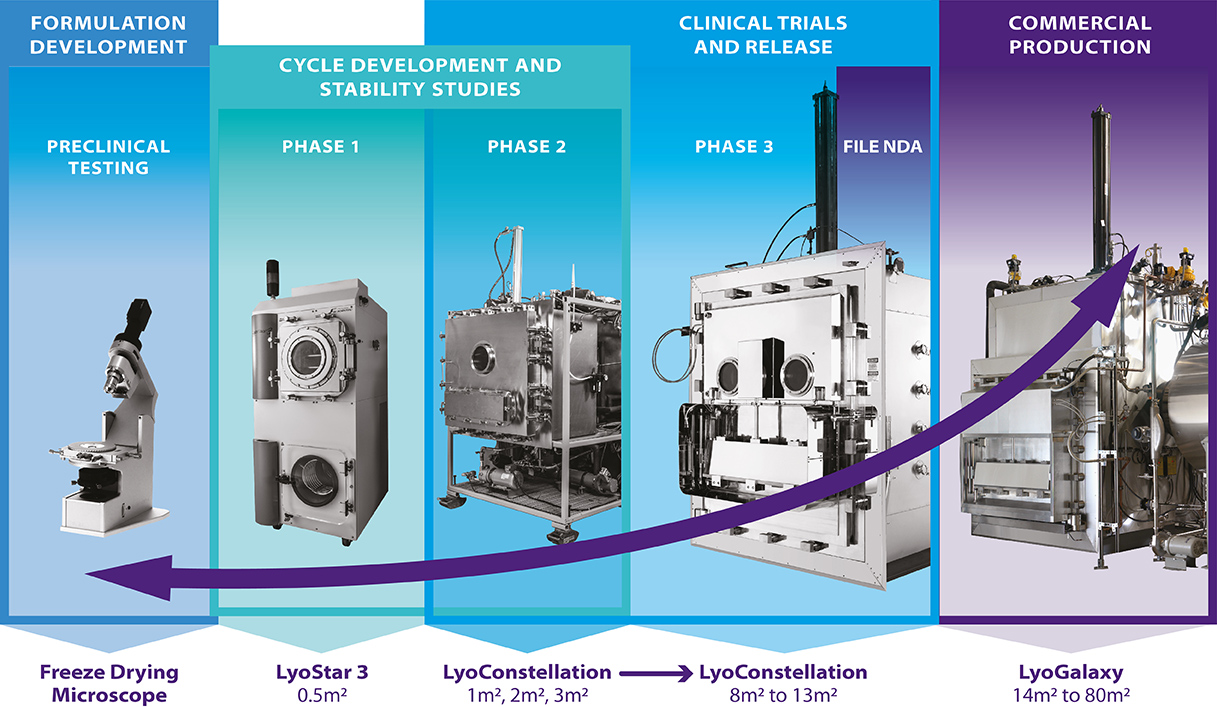

The SP Line of Sight™ Approach - Accelerate Your Formulation Development Through to Final Product

Product Description

SP Scientific Products

-

US

-

2020On CPHI since

-

3Certificates

-

500 - 999Employees

Company types

Categories

Specifications

SP Scientific Products

-

US

-

2020On CPHI since

-

3Certificates

-

500 - 999Employees

Company types

More Products from SP Scientific Products (2)

-

Product Vial Washing - Effective and Efficient

The SP i-Dositecno vial washer range consists of four models to cover a wide range of production rates including a compact footprint option for laboratory and small batch applications to clean vials with as little as 1 liter per minute WFI (Water-For-Injection) usage, as well as high-speed production a... -

Product Versatile and Complete Sterile Filling and Stoppering Solutions

SP offers a choice of machines and dispensing methods for liquid filling of oral and ophthalmic bottles, vials, syringes and cartridges. All offer the dependable sterility, accuracy and speed essential for the pharmaceutical sectors, whilst also meeting the highest quality and accuracy expectatio...

SP Scientific Products resources (2)

-

News SP Acquires Spain Based i-Dositecno

Warminster, PA – October 28 – SP Industries, Inc. (“SP”), a leading designer and manufacturer of state-of-the-art laboratory equipment, pharmaceutical fill-finish manufacturing solutions, laboratory supplies and glassware, announced today that it has acquired the assets of privately held i-Dositecno. Located in Mataro, Spain, i-Dositecno is a global provider of complete sterile filling lines for pharmaceutical, cosmetic and ophthalmic applications.

-

Whitepaper White Paper: Tackling the challenges of small batch manufacturing in fill-finish programs

This White Paper discusses development and manufacturing challenges, and highlights key considerations when evaluating product development tools, selecting equipment, and optimizing small batch fill-finish lines.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance