CPHI Barcelona 2023 – the Product Innovation sessions: tired of leaking softgels?

Learn how to improve softgel seams and process efficacy from GELITA's presentation in the Product Innovation theatre from the Content hall at CPHI Barcelona in October 2023.

In this product innovation session, led by Jessica Pföhler, Global Marketing at GELITA and Holger Becker, Head of Global Application Technology & Product Development, GELITA offers a solution to a long standing issue in capsule technology – leaking soft gels. They introduce GELITA's latest innovation, EASYSEAL®: a pharmaceutical grade Softgel gelatin, that improves capsule seams.

The seals on softgel capsules are notoriously weak and prone to leaking, which can cause problems down the line in filling, packaging, and use.

Pföhler highlights some of the difficulties associated with leaking softgels, including the added expense.

‘They reduce the yield of your production, they make you sort out leaking capsules, you're losing raw materials, which is especially painful when it comes to expensive fills and overall you simply increase your production costs.’

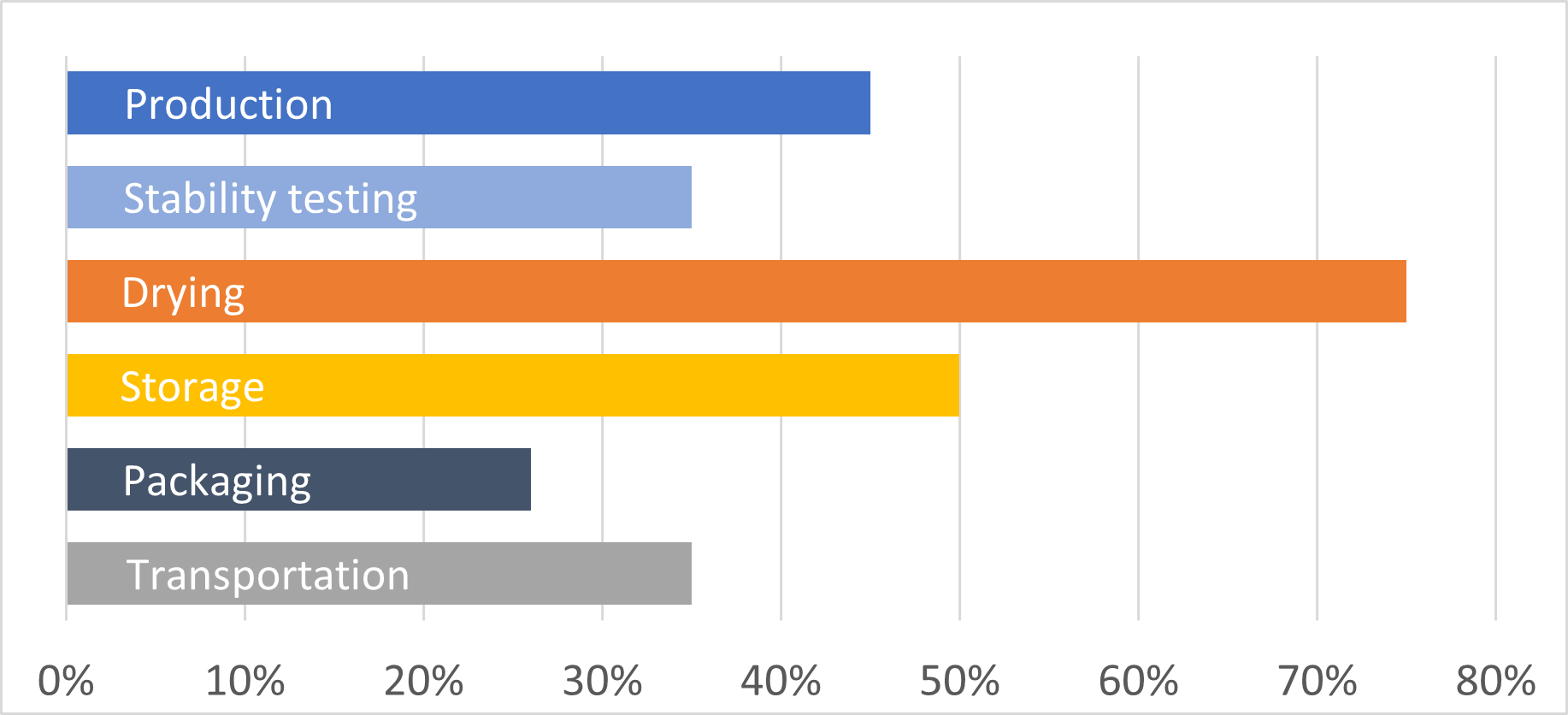

From a survey GELITA undertook from 20 experts in softgels, they discovered what the most common causes of leaks are, and what measures are usually taken to prevent them.

The responses highlighted the following as main causes of leaks:

Measures that experts like to take include adjusting machine speed or drying time, and some even advocate for the adjusting of the packaging for the softgels themselves. One thing that was abundantly clear was that the potential for leaking can depend on the fill. To understand this better and see how to improve, GELITA undertook trials to test different fill systems and materials, putting the softgels through their paces with some rigorous testing conditions.

For this, Becker stepped in to give an overview of the trials.

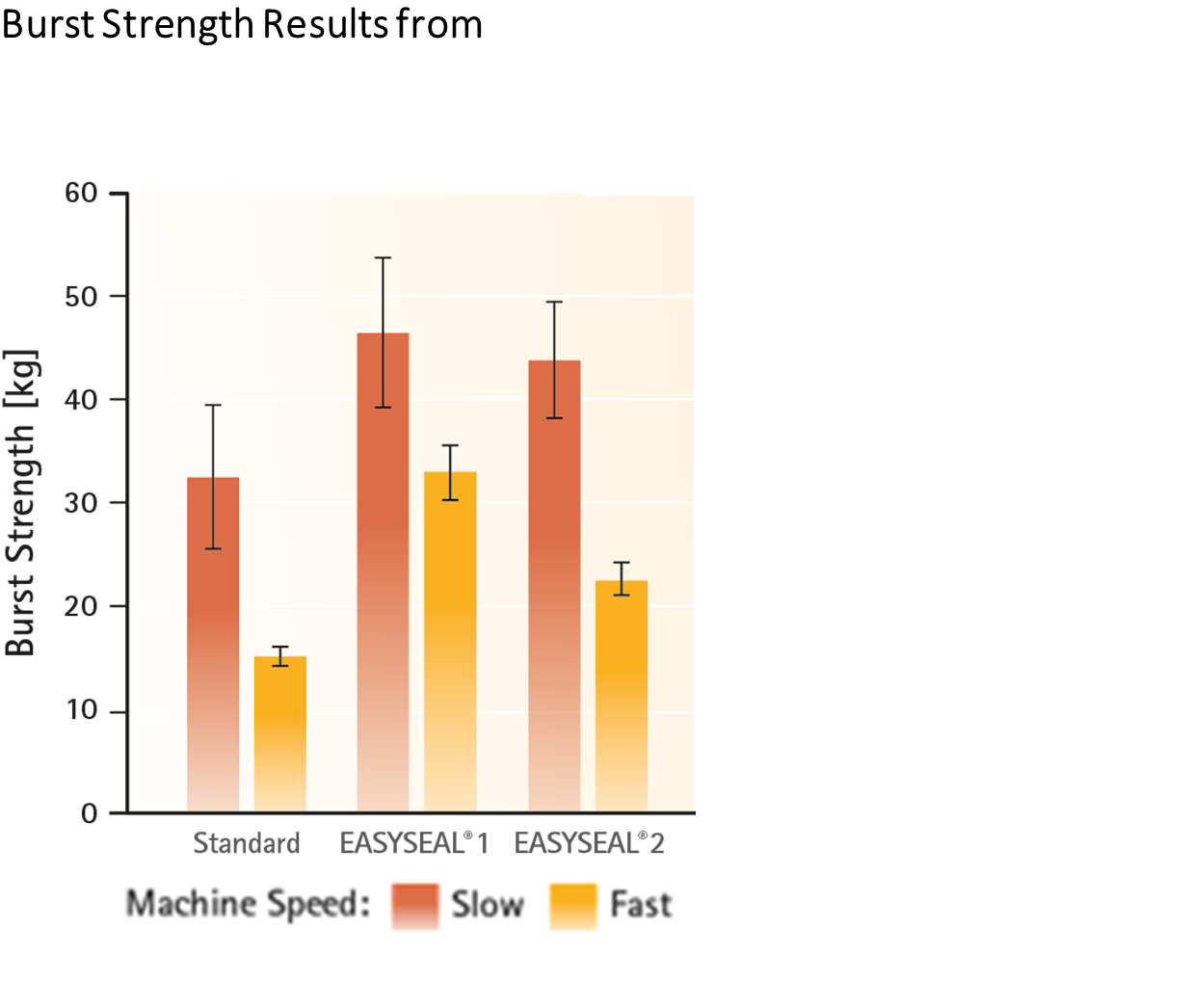

The performance of EASYSEAL® of different gel mass compositions was assessed under different conditions of speed and temperature.

The resistance of the capsule to bursting was measured as burst strength, and compared at different speeds. The results showed that EASYSEAL®1 had a greater burst strength at both slow and fast speeds compared to the standard gelatin seal.

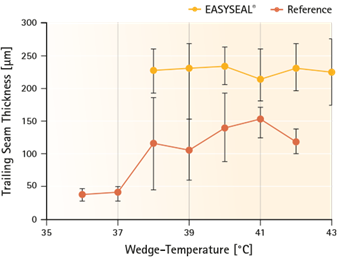

When tested under different temperatures, the EASYSEAL® capsule kept a significantly greater trailing seam thickness at higher wedge-temperatures.

Becker states that when you use the standard seam, you need to find the optimum temperature where the seams have the best stability and best thickness. For this, you need a lot of experience from the operator at the soft capsule machine to find the optimum temperature as it varies from formulation to formulation.

The team at GELITA went on to test five different fill formulations, for burst strength and trailing seam thickness:

1. Krill oil (gel mass not aged)

2. Krill oil (gel mass aged)

3. Highly loaded suspension (based on sunflower oil)

4. Polysorbate-based fills

5. Soy Lecithin

They go on to mention the importance of taking into account the spreading properties of the fills, how they stabilise the formulation, and it’s emulsification properties and bioavailability – properties that are critical for fill formation.

The benefits of using EASYSEAL® compared to standard gelatin include a 50% increase in trailing seam thickness, allowing a speed increase of around 35%, a faster drying time by 20 hours, decreased leaker formation by 89% in one trial, and a 33% increase of capsule output per hour, all equating to a huge increase in productivity.

Questions from the session covered the difference in the EASYSEAL® composition and manufacturing process. Pföhler answered that the softgel was much more homogeneous, "gelatin is a biopolymer with a wide range of molecular size distribution and we have a very good solution to have a more homogeneous gelatin with regard to this composition" – summarising that differences in the EASYSEAL® portfolio and standard gelatin is derived from the manufacturing techniques of the two products.

GELITA has a strong controlled-release portfolio, providing innovative solutions from a single source. See the full presentation from GELITA at CPHI Barcelona on demand now.

Related News

-

News CPHI Pharma Awards 2023 – Supply Chain Excellence Winners: Catalent Case Management Services

After another year of impressive nominations for the CPHI Pharma Awards our winners were announced at CPHI Barcelona in October. In this series of interviews, we speak to the people and teams behind the award-winning projects, concepts, and technologie... -

News CPHI Pharma Awards 2023 – API Development and Innovation Winners: Snapdragon Chemistry, a Cambrex Company

After another year of impressive nominations for the CPHI Pharma Awards our winners were announced at CPHI Barcelona in October. In this series of interviews, we speak to the teams behind the award-winning projects, concepts, and technologies. -

News Navigating the Future: Challenges and Opportunities in Pharma Innovation and Investment – CPHI Barcelona 2023 Roundtable Report

In this comprehensive downloadable report, hear from a range of experts in finance and investment in the pharma industry on what investment trends will be shaping the future of the industry, in Catalonia, and the wider world. -

News CPHI Barcelona 2023: Partnering for Success – Managing Outsourcing Relationships to Optimise Manufacturing Operations

During CPHI Barcelona 2023, insightful content sessions offered attendees the chance to explore trending topics with expert speakers and panellists. Here, we summarise what the pharma industry and supply chain are talking about the most. -

News CPHI Podcast Series: The 2023 Retro – what have we learnt from the past year in pharma?

Welcome to the last episode of 2023! Digital Editor Lucy Chard is joined by her teammates in a special retrospective episode to close out the year. Guests Vivian Xie, Editor for CPHI Online and Tara Dougal, Content Director for Pharma, discuss their hi... -

News CPHI Pharma Awards 2023 – Accelerating Innovation Winners: React4Life

After another year of impressive nominations for the CPHI Pharma Awards our winners were announced at CPHI Barcelona in October. In this series of interviews, we speak to the teams behind the award-winning projects, concepts, and technologies. -

News CPHI Pharma Awards 2023 – Regulatory & Compliance Winners: Lambda Therapeutic Research Ltd.

After another year of impressive nominations for the CPHI Pharma Awards our winners were announced at CPHI Barcelona in October. In this series of interviews, we speak to the teams behind the award-winning projects, concepts, and technologies. -

News CPHI Barcelona 2023: Loading Potential – Artificial Intelligence for Pharma Manufacturing

During CPHI Barcelona 2023, insightful content sessions offered attendees the chance to explore trending topics with expert speakers and panellists. Here, we summarise what the pharma industry and supply chain are talking about the most.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)