Dynage

About Dynage

Certifications

Categories

-

IT

-

2023On CPHI since

-

5Certificates

-

25 - 49Employees

Company types

Primary activities

Meet us at

CPHI Milan 2024

Fiera Milano, Italy

08 Oct 2024 - 10 Oct 2024

Products from Dynage (3)

-

Product BIN / DRUM LINE

Our line of Stainless Steel BIN and DRUM are suitable for all handling / manipulation of API and OSD, powders, liquids and viscous in pharmaceutical processes.

Made on standard models and / or according to customer / plant construction spefications, they are durable, solid ans reliable. q... -

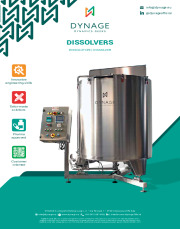

Product MIXER / DISSOLVER

Our line of stainless steel mixer/dissolvers is suitable for all pharmaceutical application fields, the systems are fully customizable according to user needs.

There are many combinations, mixing, dissolution and thermoregulation of the product, liquid analysis, weighing and dosing us... -

Product MIXER / DISSOLVER

Our line of stainless steel mixer/dissolvers is suitable for all pharmaceutical application fields, the systems are fully customizable according to user needs.

There are many combinations, mixing, dissolution and thermoregulation of the product, liquid analysis, weighing and dosing us...

Dynage Resources (4)

-

Technical Data DISSOLVERS - Dynage

Dynage stainless steel dissolvers are suitable for all pharmaceutical and cosmetic application fields, oursystems are fully customizable according to customer needs. Many different combinations are available:mixing, dissolution and thermoregulation of the product, liquid analysis, weighing and dosing with dedicatedsensors. Processes can be monitored with accessories such as: specola, portholes, in-line visual specola.Optional sensors include: programmable weighing systems that, combined with controlled valves, managerecipe dosing, process analysis sensors such as conductivity meters, phmeters and others. They can beequipped with temperature control systems (chillers/electric heaters) and clean-in-place – CIP systems. Theyare also available configured for processing under vacuum or positive pressure conditions according to PEDregulations. Processes are managed via electromechanical panels, HMI or SCADA systems. They are alsoexecutable to operate in an ATEX environment. -

Technical Data MELTERS - Dynage

Dynage stainless steel melters are suitable for all pharmaceutical and cosmetic application fields, the systemsare fully customizable according to customer requirements. Entirely made of stainless steel they can beexecuted in either using Aisi 316L or Aisi 304L. In terms of mixing apparatus, they can be supplied in differentvariants including: mixing anchor (for mixing the most solid matrices), dispersion propeller (to dispersepowders/microelements or to facilitate the dissolution of solid portions for fatty/waxy phases). Our melterscan be heated by steam, hot water/diathermic oil in an insulated outer jacket heated by electric heatingelements to increase/control the tank temperature and implement the transition from solid to liquid phase ofthe compound to be processed. All melter models, for cosmetic or pharmaceutical field, are fully configurablewith additional accessories according to individual customer’s needs. -

Technical Data BULK MATERIAL HANDLINGS - Dynage

Dynage stainless steel bin and drum bulk handling and process container line is suitable for all API and OSD,powder, liquid and viscous handling in pharmaceutical processes. Manufactured on standard models and/oraccording to customer/plant specifications, they are durable, robust and reliable. The utmost attention is paidto the selection of quality raw materials and components and to pharmaceutical-grade finishes and surfacetreatments. Production starts from sheet metal and process control is total, from laser cutting tostamping/forming, welding/assembly and final finishing. -

Technical Data MIXERS - Dynage

Dynage stainless steel mixers apply to all pharmaceutical and cosmetic uses, our systems are fullycustomizable according to customer needs. They can perform multiple operations: mixing, productdissolution, thermoregulation, liquid analysis, weighing and dosing with dedicated sensors. Visualmonitoring of the process is provided by various accessories such as: visual specola, portholes, in-linevisual specola. Sensors that can be applied include programmable weighing systems that, combined withcontrolled valves, manage recipe dosing, process analysis sensors such as conductivity meters, phmetersand others. They can be configured with temperature control systems (chillers/electric heaters) andclean-in-place – CIP systems. They are also available prepared for processing under vacuum or positivepressure conditions according to PED regulations. Processes are managed via electromechanical panels, HMIor SCADA systems. They are also executable to operate in an ATEX environment.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance